|

|

Post by paul8899 on Feb 4, 2012 15:02:12 GMT 1

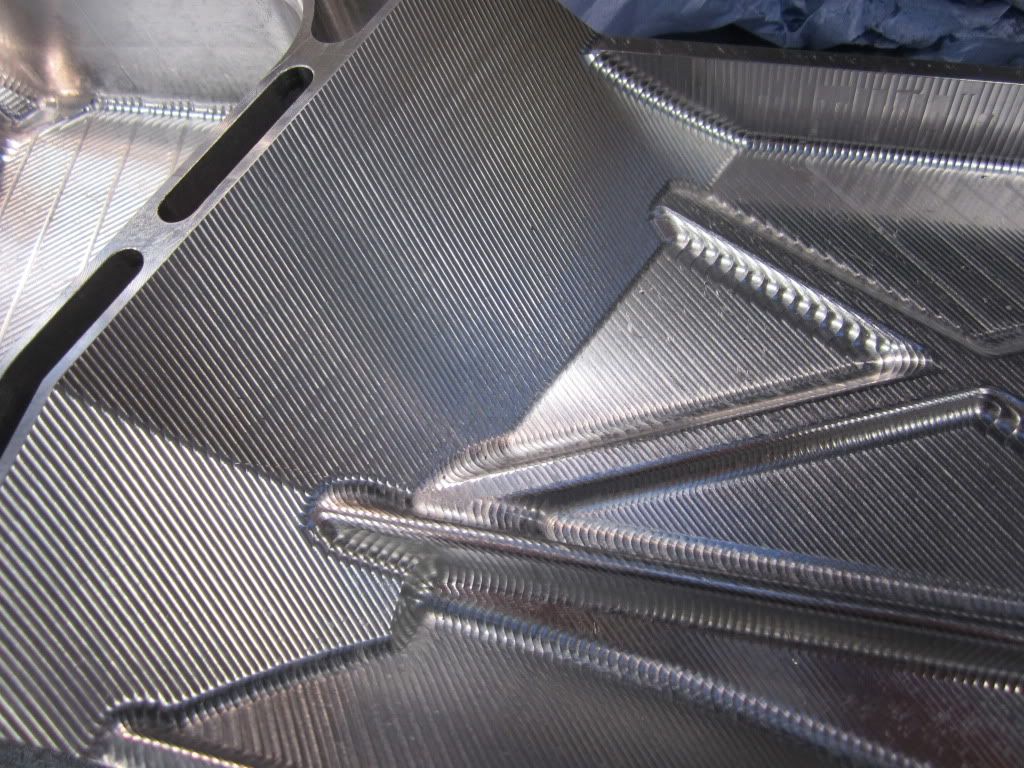

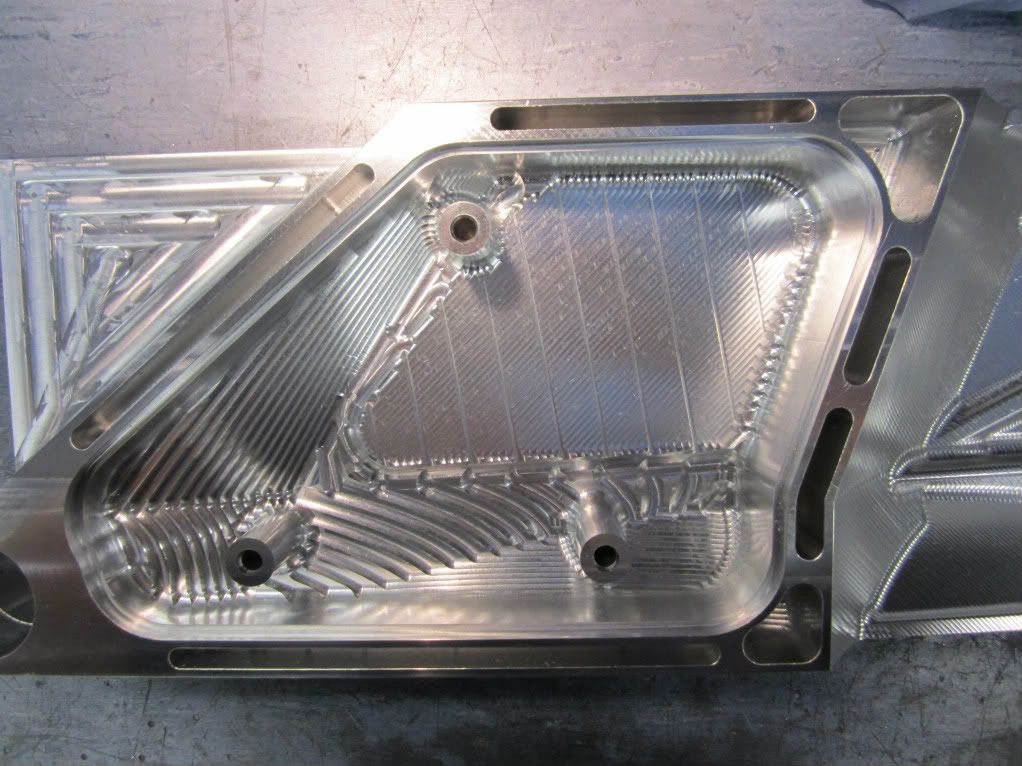

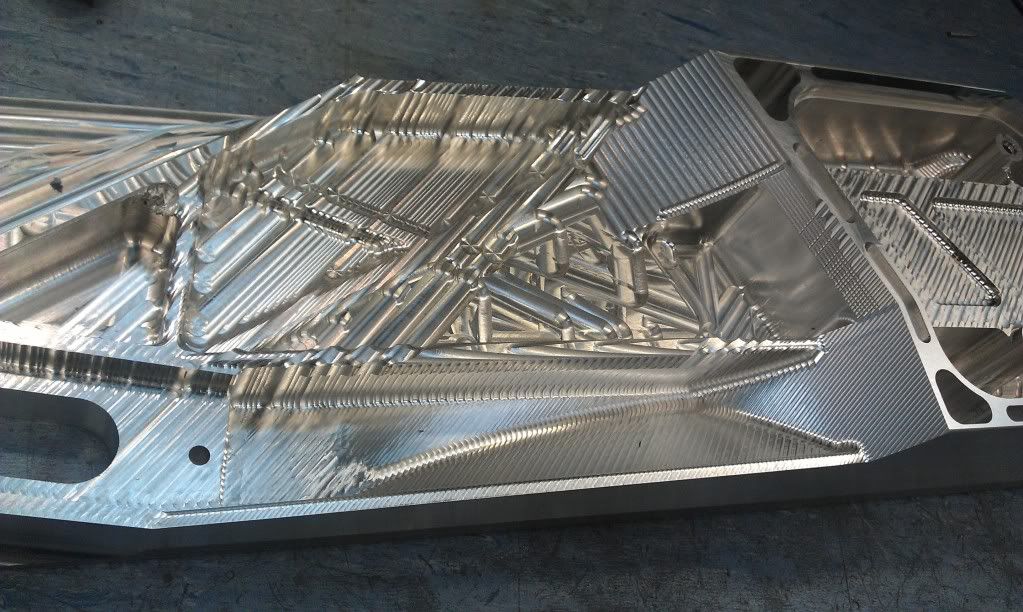

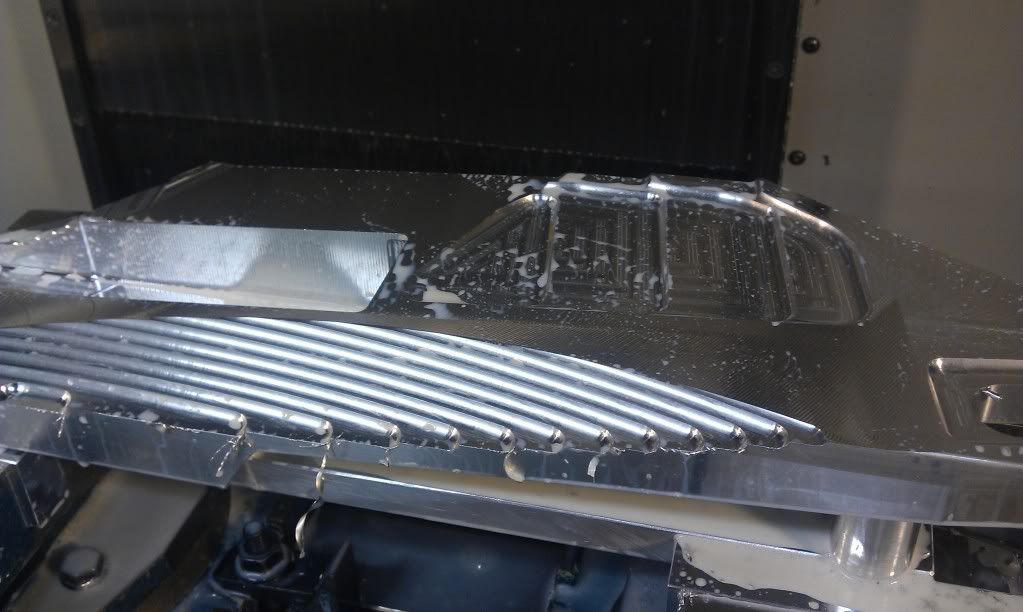

Here's a couple of pictures of the inside of the brake side arm    Here's what it looks like with the centre section roughly in place   At a guess I'd say that what's left of the arm now weighs around 5kg and it took 11hrs to machine. All the weight is at the front of the billet , there is virtualy no weight on the wheel end . Hope it's not going to end up too bendy ! One of cutters broke when it was running so I'm going to have to re-cut the bits it missed out, shouldn't take too long to do . Just have to make sure I pick the job up right or it will look a bit crap While I was feeling lucky I thought that I'd have a go at finishing the centre section off and after 3 hours machining it now looks like this   Now that I've finished the middle bit off I can now finally weigh it and it now weighs  The scales say 3kg but as they aren't calibrated I'm going to say it's slightly under 5kg , and a total machine time of around 35hrs. Not too bad for an amateur , It had better fit !! |

|

|

|

Post by tunneruk on Feb 4, 2012 19:28:18 GMT 1

That just takes the piss!!!

I'm a Toolmaker by trade (No longer practising now though)

I genuinely gasped when I saw that first photo of your last post.

That is utterly utterly gorgeous.

I can't wait to see more!

|

|

|

|

Post by paul8899 on Feb 18, 2012 14:03:44 GMT 1

That just takes the piss!!! I'm a Toolmaker by trade (No longer practising now though) I genuinely gasped when I saw that first photo of your last post. That is utterly utterly gorgeous. I can't wait to see more! Thanks , to be honest it is getting a bit silly now but I've told myself that once this is done ( and it hopefully fits ) then I'm going to make an effort to just finish it off . This may or may not be entirely true though  |

|

|

|

Post by paul8899 on Feb 18, 2012 14:05:46 GMT 1

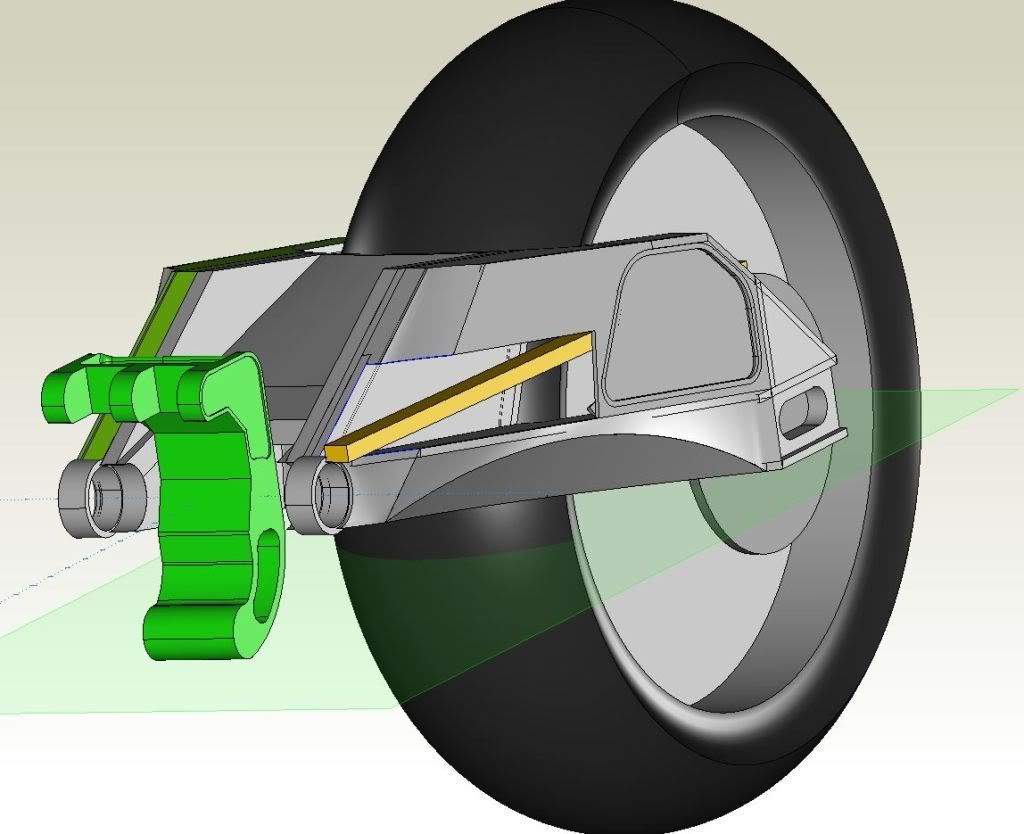

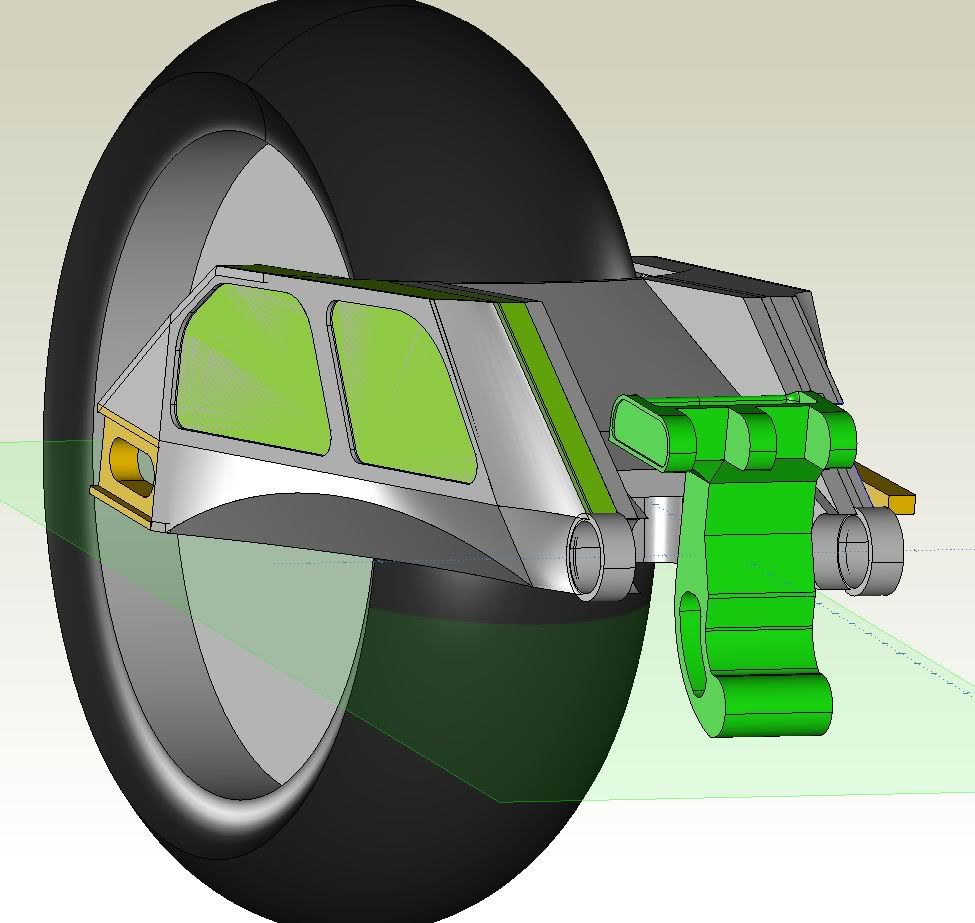

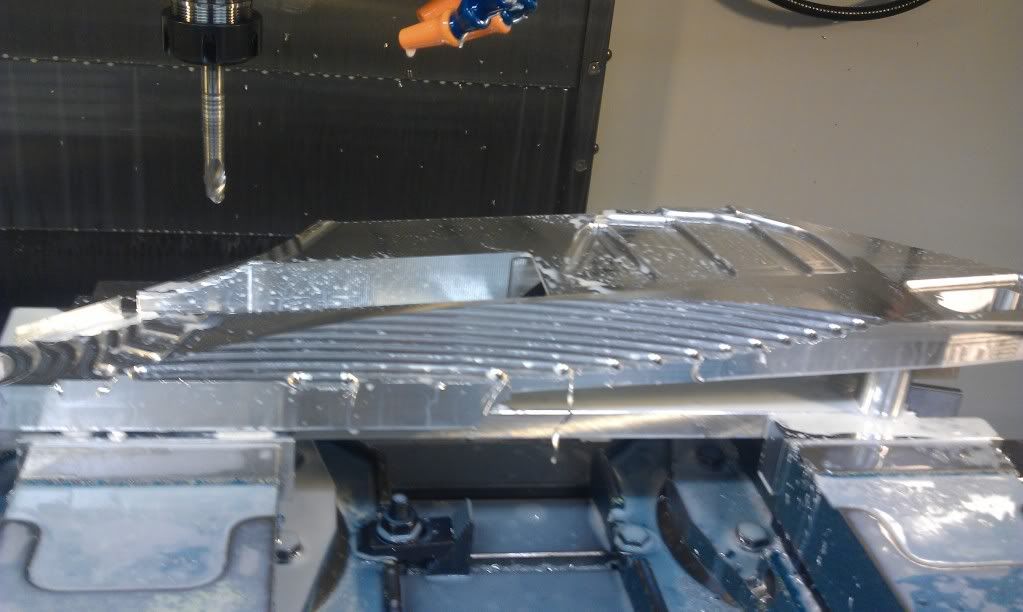

I finally managed to find a spare 15hrs on the machine and it now looks like this     For some reason the cam program decided to plunge into a part that had a bit too much metal left in and smashed the cutter into lots of little bits which is why the back section isn't finished. Once I've altered the program so it doesn't try and kill itself I'll re-set the arm and re-cut it , which will hopefully be next week . I really hope this fits !! This is what I'm hoping it will end up looking like   |

|

popeye

Weekend rider

Posts: 86

|

Post by popeye on Feb 19, 2012 9:13:11 GMT 1

Hi Paul,

I hope you've sent these pictures to the "Tate Gallery"

Regards Wayne.

|

|

lcolin

Thrash Merchant

Posts: 497

|

Post by lcolin on Feb 22, 2012 1:03:31 GMT 1

Can't wait to see an update on this? Its looking incredible.

|

|

|

|

Post by paul8899 on Mar 2, 2012 21:40:35 GMT 1

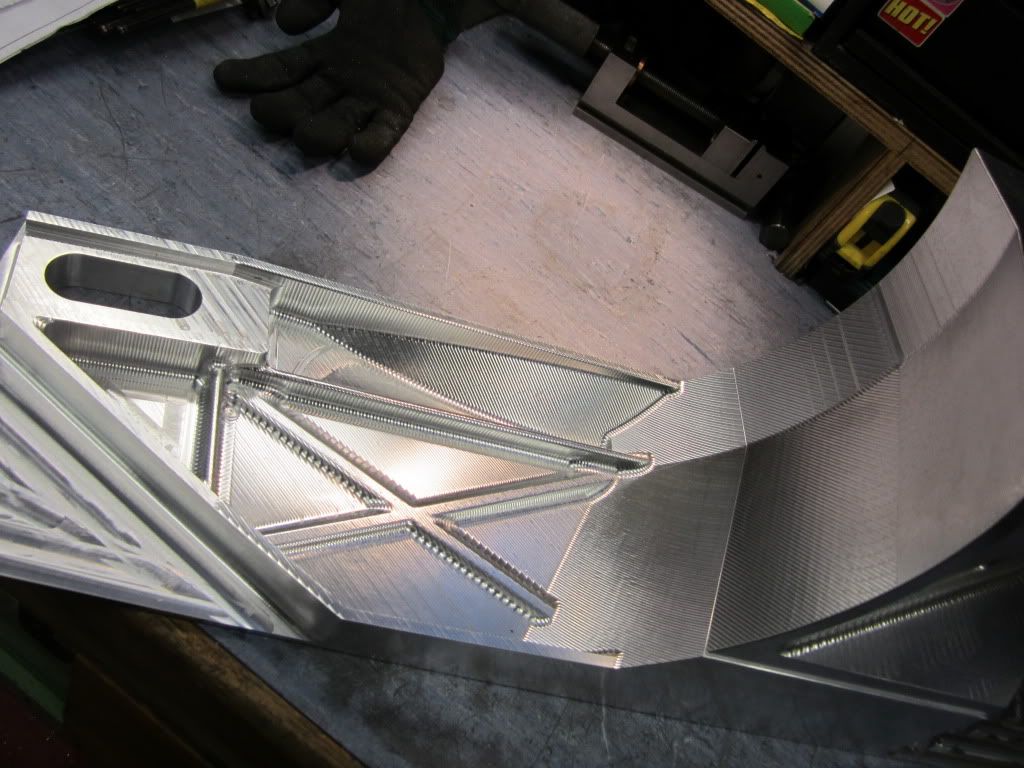

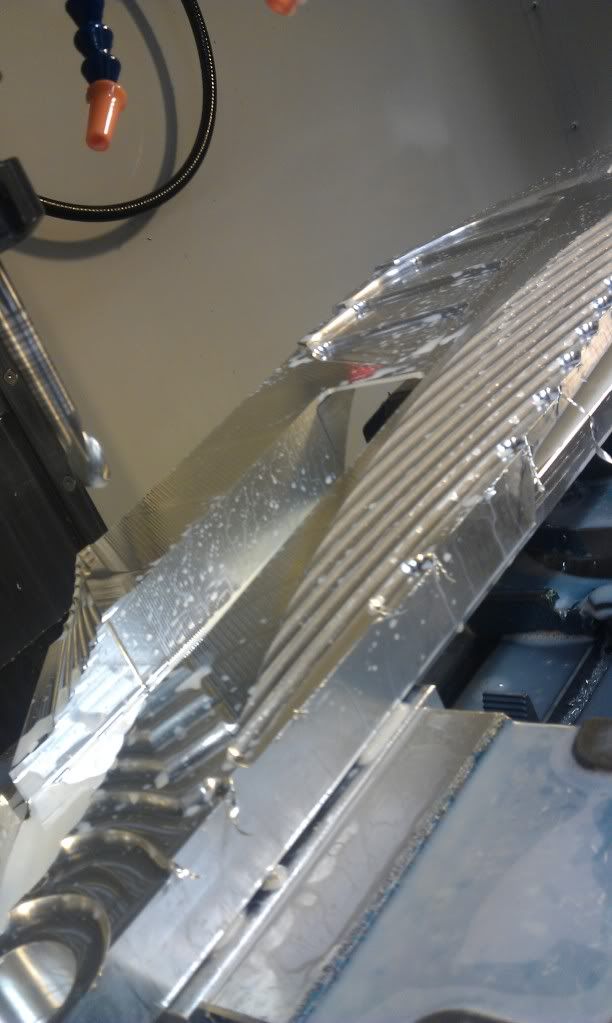

I managed to find the time to have a go at the final machining of the chain side arm so I set it running as I left work so it should be ready for me in the morning. Normally once I've set the mill running I watch it for a bit to make sure that the first cut is as I want it then go home and forget about it until the next morning BUT being as I haven't been too lucky job-wise I gave in and popped in to check that it hasn't machined through the vice , cut the job in half or something worse. So after a nervous drive I was greeted with this  Pointing taken care of by Olly     Barring any major catastrophe's I'll have a finish machined arm waiting for me in the morning  |

|

|

|

Post by marsbar350 on Mar 2, 2012 22:11:50 GMT 1

work of art there paul  keep the pics coming ;D |

|

|

|

Post by paul8899 on Mar 2, 2012 22:52:05 GMT 1

Thanks, I'm really pleased with how it's turning out I'll post some better pictures tomorrow afternoon  |

|

|

|

Post by paul8899 on Mar 3, 2012 14:41:57 GMT 1

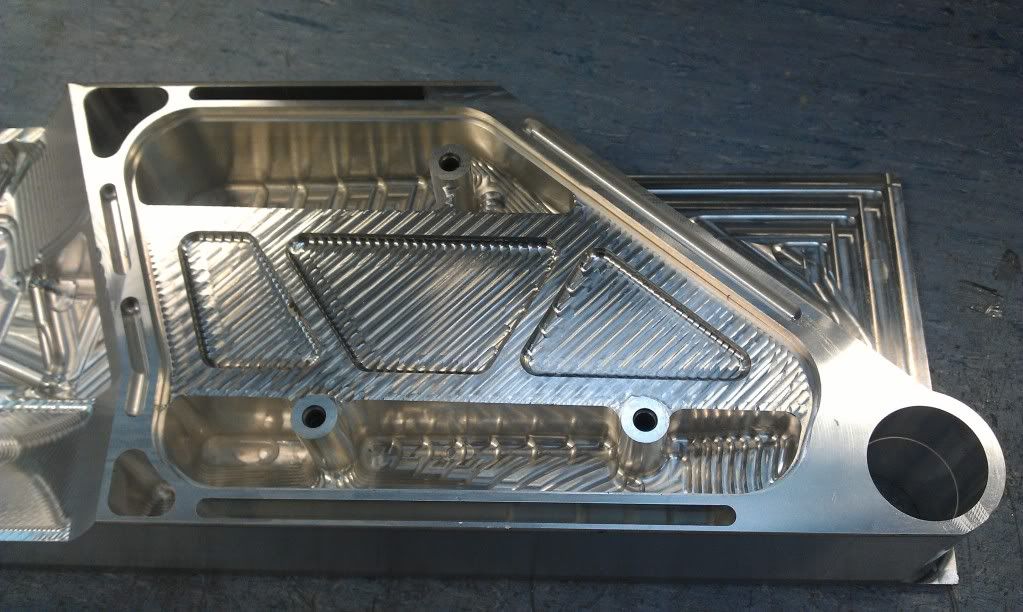

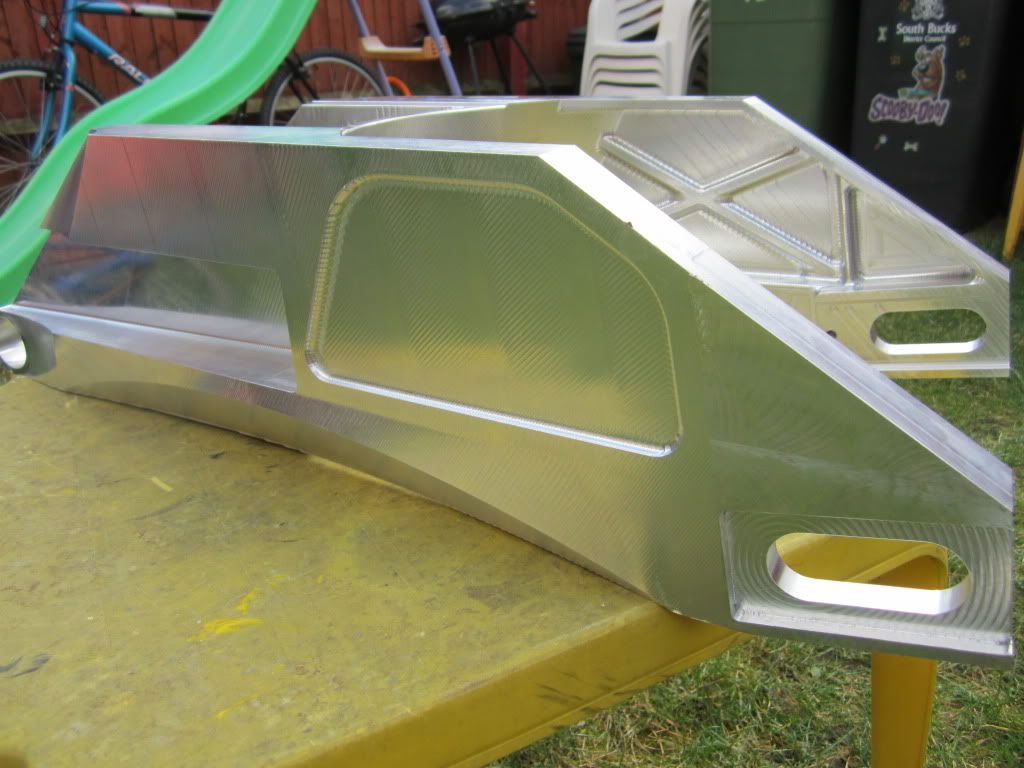

Here's a few pictures you might like to have a look at       There's still a little bit of machining and finishing off left to do but it's almost ready ! Next job to do is to machine the clearance into the centre section to clear the bearing tubes, make some temporary tubes and then I'll finally be able to see if it fits  I gave in and weighed one of the arms and it was 2.7kg and the final weight is 9kg ( on my accurate bathroom scales  ) At least this keeps the scrap man happy with the 91kg of swarf I produced  I ran some highly technical and accurate stress analysis on the arm once it was built, first off I tried a light stress test just in case the arms snapped Passed with flying colours , no snapping   Second test was with a bit more weight , 7 stone Passed again ( getting good at this )  Last test was having a big lump bounce up and down and passed again   I now pronounce this arm fit for use , if it fits that is  |

|

|

|

Post by Splodge on Mar 3, 2012 15:16:09 GMT 1

That sure is a superb one off swing arm, I bet you don't get too many orders for a replica, How ever much would that cost ?  |

|

|

|

Post by paul8899 on Mar 3, 2012 15:48:02 GMT 1

That sure is a superb one off swing arm, I bet you don't get too many orders for a replica, How ever much would that cost ?  Thanks, its not too bad for a first attempt  Surprisingly enough there hasn't been anyone ask for me to make one, think my email must be playing up  I'm not sure on cost but it took roughly 80hrs to design ,100hrs to machine and used about 110kg of ally  |

|

|

|

Post by lcowner on Mar 3, 2012 17:01:22 GMT 1

maybe thats why no one has asked for a price! but go on then how much wud it be to get it done ?

|

|

|

|

Post by paul8899 on Mar 3, 2012 17:22:51 GMT 1

If you could get a machine shop to do the job then I'd guess at around 9k

|

|

|

|

Post by lcowner on Mar 3, 2012 20:36:36 GMT 1

is that just for the swinger ?wow thats unreal ur a very talented man respect!big time

|

|

|

|

Post by paul8899 on Mar 3, 2012 21:17:52 GMT 1

is that just for the swinger ?wow thats unreal ur a very talented man respect!big time Yes thats just for the swinger , if you work it as being £40 per hour for the design, machine and fitting time then that's 7k ish plus the metal. If I didn't have access to the machinery and other bits then there's absolutely no way I would ever be able to afford to get anything done that I've made for this bike. Thanks for the positive comment but I had to call in a lot of favours to get this made and I think I'll be paying them back for quite a while  |

|

|

|

Post by billy on Mar 4, 2012 19:14:04 GMT 1

Amazing work! Programming the CNC mill must have been so damn time consuming eh? Anyway, hats off, great job etc.  |

|

|

|

Post by paul8899 on Mar 10, 2012 19:43:33 GMT 1

I couldn't stand the suspense anymore so I decided to have a proper go at seeing if the arm would fit in and line up as I think (hope) it should. After attacking the bottom footrest mounts with a file for half an hour they now cleared the spar, and with the arm in almost the right place it looks a bit like this    I checked the alignment of the shock mount to the one that I had welded to the frame and luckily enough it lines up , so that's one problem out of the way. Speaking of problems , there's a small issue with the the front of the arm hitting the top footrest mount which means that I'm going to have to get them re-welded  I'm hoping that once this is done then it will have enough travel then I can carry on with the rest  |

|

|

|

Post by ianboom on Mar 10, 2012 20:45:25 GMT 1

That is one amazing bit off engineering and machining.

Love it, almost a shame to put it on a bike!

Ianboom.

|

|

|

|

Post by paul8899 on Mar 10, 2012 21:26:55 GMT 1

Thanks  If I can't get it to fit properly I'll use it for a paperweight ! |

|

|

|

Post by bandit123456 on Mar 21, 2012 22:13:24 GMT 1

thats a work or art that is

|

|

|

|

Post by tunneruk on Oct 12, 2012 13:44:24 GMT 1

Has this build died a death?

|

|

|

|

Post by paul8899 on Oct 12, 2012 19:28:56 GMT 1

Has this build died a death? Well, it has been put on the back burner until I get the TZR finished . The reason it's been put to one side is that when I designed the arm I didn't leave enough room for the back of the frame , so there's a "slight " interference between the arm and frame when it's near full travel. There's two ways I can get round this , one is to modify the back of the frame so it clears the arm . This would mean a LOT of work , plus I'm not too sure about removing lumps from the pivot area which is thin enough as it is. The second is that I'll have to re-design the arm so it clears the arm . I decided to re-do the arm because I want to do this right , rather than messing about too much. I know how the arm needs to be modified , just have to draw it up. Once I've stopped sulking about it not fitting I'll make a start on finishing it off. |

|

|

|

Post by spencerd on Nov 29, 2012 23:18:38 GMT 1

You's an Ingineer mate, you'll work it out, keep the enthusiasm juices flowing!!

|

|

|

|

Post by zx9landie on Sept 22, 2013 22:56:33 GMT 1

cant wait for the next installment

|

|

|

|

Post by AndyYam on Sept 25, 2013 22:25:47 GMT 1

Look forward to an update. Planning on building a TZR350YPVS in the not too distant future from a 4dl belgarda.

|

|

|

|

Post by yazza54 on Apr 12, 2014 15:21:52 GMT 1

You still building this mate?

|

|

|

|

Post by rob99 on Apr 13, 2014 7:34:48 GMT 1

Fantastic billets of alluminum looking very well machined i wish i worked on a miller and not on a lathe

Looking brill keep pushing on it will be realy nice when finnished

|

|

popeye

Weekend rider

Posts: 86

|

Post by popeye on Mar 1, 2015 6:56:29 GMT 1

Paul,you have PM.

|

|

2taol

Thrash Merchant

Posts: 378

|

Post by 2taol on May 8, 2015 17:00:08 GMT 1

any updates on this savage project?

|

|