|

|

Post by 29davyt on Jul 9, 2022 19:20:04 GMT 1

Shear brilliance !! You do make it look sooo easy Dusty, might even split mine and sort the whining 6th gear out now👍

|

|

|

|

Post by dusty350 on Jul 10, 2022 8:45:49 GMT 1

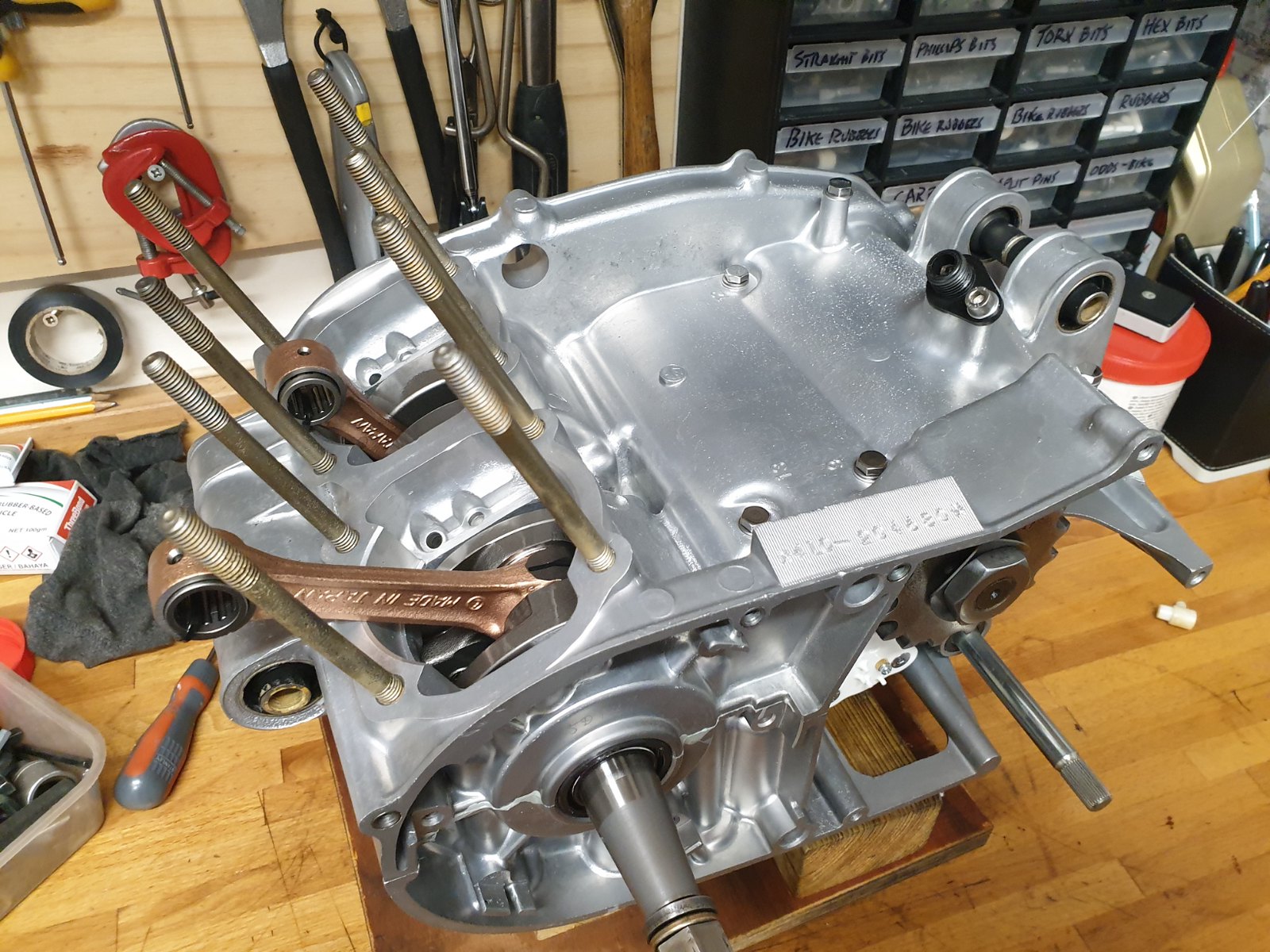

They are easy to rebuild. The strip down is usually the part that can cause headaches, but once apart, the build back up is fairly straightforward. The bonus is most of the parts needed are available as genuine Yamaha, and often from stock. Quality pattern alternatives are available where genuine is nla, so we are pretty well covered. Being able to get the parts is half the battle, so we are very lucky in that respect  The drive shaft is cleaned, inspected and coated in fresh gear oil, and the newly oiled bearings fitted to each end. This can now be lowered into position in the case, and you can now spin the gears to make sure the gears mesh properly. Fitting the gear clusters is simply a case of lowering them into the case. The only thing you need to line up are the tracks on each cluster that the selector forks act upon;  20220706_205611 20220706_205611 by dusty miller, on Flickr And that's the gearbox done. The last component to fit to the bottom case will be the crank. This engine had a crank that was ok, but needed a rebuild. The rotor side bearing was worn enough to allow it to slide off the end of the crank. I called Paul at PJME, and have bought a new crank from him. I had one on a previous build and it's fantastic quality, and built up ready within a week. Paul only uses top quality parts in these cranks, so I dropped off my 350 barrels for resleeving, and picked up the crank at the same time;  20220710_083206 20220710_083206 by dusty miller, on Flickr Dusty  |

|

|

|

Post by bezzer on Aug 6, 2022 10:29:20 GMT 1

Thanks Dusty, for taking the time to post this build, including all of the detail, photos, part numbers, hints/tips etc. It really is an invaluable resource for any of us rebuilding a motor.

Keep up the great work mate. bezzer.

|

|

|

|

Post by dusty350 on Aug 6, 2022 16:59:11 GMT 1

No worries mate, glad it's helpful. Will be back on it now. Been mega busy helping out the kids with their first homes - both have bought at the same time - but that's all done now bar a couple of jobs, so I can focus a bit more on garage stuff now  Dusty  |

|

|

|

Post by dusty350 on Aug 16, 2022 7:41:27 GMT 1

Crank fitment time ! I bought a shiny new crank from Paul at PJME when I dropped my barrels off to him. Top quality components, and built up by Paul and the team within a week of ordering  ;  20220815_081652 20220815_081652 by dusty miller, on Flickr I will keep the old crank for a rainy day, or a door stop !! Don't forget the half ring, that fits in the inner groove in the casing on the primary side;  20220815_081153 20220815_081153 by dusty miller, on Flickr 2 new Yamaha crank seals. £15.79 for the small generator side, £12.82 for the primary side. Apply red rubber grease to the seal lips, and the tapered surface of the crank to avoid damage to the seal, and make for an easy fit;  20220815_083137 20220815_083137 by dusty miller, on Flickr  20220815_084255 20220815_084255 by dusty miller, on Flickr Fit the generator side seal before fitting the crank in the case. The primary side doesn't contact the crank directly, so can be fitted when the crank is in. With the seal fitted and the pips lined up on the bearings, you can lower the rank into the case;  20220815_084028 20220815_084028 by dusty miller, on Flickr At this point the crank will rock in the case. The centre labrynth seal needs "seating" into the casing to allow the crank bearings to sit into their pockets. A gentle tap down with a wooden drift will seat the ali labrynth seal without damaging it;  20220815_084037 20220815_084037 by dusty miller, on Flickr Once bedded in, there will be no rocking as you rotate the crank. The primary side seal can now be fitted, with red grease on the lips;  20220815_084439 20220815_084439 by dusty miller, on Flickr And castellations towards the bearing !!;  20220815_084436 20220815_084436 by dusty miller, on Flickr With regards to the generator side bearing, it isn't "sided" as such, but I always fit mine with the "ARS" logo on the outer edge of the seal facing away from the bearing;  20220815_084600 20220815_084600 by dusty miller, on Flickr Dusty  |

|

|

|

Post by arrdy350 on Aug 16, 2022 10:25:20 GMT 1

Great detail as always Dusty. Very helpful thread 👍

|

|

|

|

Post by shaunthe2nd on Aug 16, 2022 13:57:43 GMT 1

'The strip down is usually the part that can cause headaches, but once apart, the build back up is fairly straightforward.'

Agreed Dusty, once you have fought the rotor off, its the little M6 buggas that give the most resistance.

|

|

|

|

Post by yamark on Aug 16, 2022 16:56:50 GMT 1

Gorgeous Dusty, another amazing engine build. Glad to see you didn't save a few quid and fit Yambits crank seals  |

|

|

|

Post by dusty350 on Aug 17, 2022 21:00:42 GMT 1

Haha, no chance of Shambits rubbish in my engines - Yamaha only !!  Before I can dry fit the top case, I need to fit the tacho drive. These parts make up the drive;  20220817_152410 20220817_152410 by dusty miller, on Flickr The plastic housing that fits on top of the case gets a clean, and a new "O" ring, applied with red grease;  20220817_190941 20220817_190941 by dusty miller, on Flickr  20220817_191528 20220817_191528 by dusty miller, on Flickr  20220817_191629 20220817_191629 by dusty miller, on Flickr And from inside the case - some grease on the end of the shaft where it sits in it's support housing;  20220817_191801 20220817_191801 by dusty miller, on Flickr The drive shaft can now be fitted;  20220817_192205 20220817_192205 by dusty miller, on Flickr The drive gear goes on next, and 2 new circlips fitted;  20220817_192456 20220817_192456 by dusty miller, on Flickr  20220817_192415 20220817_192415 by dusty miller, on Flickr The locking plate has now been sorted. You may remember I had to drill a broken M5 bolt out after it snapped on stripdown. I ended up with tapping an M6 hole in the case, but needed an M6 hole in the plate. Trouble is the plate is hardened, so no easy task opening out the hole. I took the plate to my welding mate Glenn this morning, and he heated it up "cherry red" with his torch, then drilled the top hole out to M6 . He then heated it up again and placed it straight into a small tin of oil. This re hardens the plate. A file failed to make an impression on the metal, so it's deemed "hard" and ready to fit;  20220817_193033 20220817_193033 by dusty miller, on Flickr  20220817_193500 20220817_193500 by dusty miller, on Flickr With the locating pin fitted as shown, the sprocket drops on, then the washer and a new circlip;  20220817_193510 20220817_193510 by dusty miller, on Flickr  20220817_193833 20220817_193833 by dusty miller, on Flickr  20220817_193549 20220817_193549 by dusty miller, on Flickr Top case is now ready to mate to the bottom case. I will bolt it up tight and check for smooth rotation of the crank and gear shafts. Much easier to check before applying goo to the jointing surfaces  Dusty  |

|

tbones

Weekend rider

Posts: 68

|

Post by tbones on Aug 18, 2022 21:33:03 GMT 1

Thank you for showing the build...

It’s a really big effort on your part finding the extra time to photo and explain / share with us all you are doing.

👍👍

Well done you for sharing this knowledge

Dan

|

|

|

|

Post by dusty350 on Aug 19, 2022 6:30:49 GMT 1

No problem, I hope it's useful. Hope to make updates more regular now. Paul has resleeved my barrels back to standard size so I need to decide whether to cerakote them, along with the head, or go for my usual vapour blasted finish. Also need to get some more parts for it, but otherwise it should be built up fairly soon  Dusty  |

|

|

|

Post by mouse on Aug 20, 2022 6:20:19 GMT 1

This is such a useful 'step-by-step' guide, brilliant!

I really think you should print it off and have it laminated to sell, i'd have one, better than a haynes manual!

Mouse

|

|

|

|

Post by dusty350 on Aug 20, 2022 7:24:25 GMT 1

Hi mate I'm just a hobby builder, happy to share my version of how I do it. I'm sure other guys may do things differently/better, so my version will stay on the forum only. I've picked up tips and knowledge from my other engine builds when guys have commented, so hopefully each "version" gets more concise and accurate. A Haynes is a "must have" in the garage I think, but modern digital pics will always help show parts better of course, and the part number inclusion hopefully makes it easier for members without a fiche to hand. I'm waiting on a clutch push rod seal arriving today hopefully, and then I can close the cases. I did fit the top case on Thursday night and nipped up the nuts underneath to check crank and gear rotation . All is well, so top is off again. You can fit the pushrod and output shaft seals with the cases bolted up, but I prefer to do it before they are fully tightened, hence a delay. Thought I had the seal but I had 2 oil pump seals in bags, and they look alike at first glance ! Fowlers have it in stock, so fingers crossed ! Dusty  |

|

|

|

Post by dusty350 on Aug 21, 2022 20:12:36 GMT 1

So the pushrod seal turned up yesterday which meant I could close the cases up. A new tube of goo;  20220820_121904 20220820_121904 by dusty miller, on Flickr  20220820_121730 20220820_121730 by dusty miller, on Flickr I apply it using a small screwdriver, onto the lower case mating surfaces. After the dry run, some oil from the crank and the gear clusters got onto the areas you apply the 3bond too, so it's good to clean that off so it's oil free and dry and clean where you apply it. A quick double check on everything and then apply the 3bond. I leave it for a few minutes, then fit the top case. It will start to close up properly when you tighten the 8 nuts underneath and the 8 bolts on top. All are numbered in the order for tightening to make things easier. I fit the 2 seals before fully tightening the fasteners - it makes fitting them easier if the cases aren't fully bolted up;  20220820_163009 20220820_163009 by dusty miller, on Flickr Red grease on the seal lip before fitting the cleaned up sprocket spacer - pushrod will get fitted later on. I take the opportunity to lap the rotor onto the crank taper at this point. It's easier to clean off the grinding paste without the generator fitted. I use the fine paste, applied to the taper, and then push the rotor on and spin it both ways for a minute or two;  20220820_155726 20220820_155726 by dusty miller, on Flickr  20220820_155956 20220820_155956 by dusty miller, on Flickr Clean off the residue and it's done;  20220820_160452 20220820_160452 by dusty miller, on Flickr Spin the engine around, and I can fit the cleaned up bearing retainer, and the baffle plate;  20220820_162530 20220820_162530 by dusty miller, on Flickr Then the first thrust washer and the clutch basket spacer;  20220820_162650 20220820_162650 by dusty miller, on Flickr I cleaned up the sprocket, and bought a new lock washer;  20220820_163129 20220820_163129 by dusty miller, on Flickr  20220820_163122 20220820_163122 by dusty miller, on Flickr That's fitted loosely for the moment. Next job is to clean and fit the generator, and buy a new clutch basket;  20220821_170509 20220821_170509 by dusty miller, on Flickr Dusty  |

|

|

|

Post by donkeychomp on Aug 21, 2022 21:41:53 GMT 1

Looks so, so good Dusty. Great work as always!

Alex

|

|

|

|

Post by charles13 on Aug 22, 2022 0:57:11 GMT 1

Dusty, those cylinder studs look new did you replace them?

|

|

|

|

Post by JonW on Aug 22, 2022 1:43:08 GMT 1

very nice Dusty!

|

|

|

|

Post by dusty350 on Aug 22, 2022 6:38:16 GMT 1

Cylinder studs went through the vapour blasting process which cleans them up, so not new  Dusty  |

|

|

|

Post by dusty350 on Aug 23, 2022 21:12:50 GMT 1

I removed the generator and rotor from the 250lc as it was virtually mint, and the loom has all it's plugs intact. There is the reg/rectifier missing on the one that came with the 350, so I will deal with that in the future when I am looking for a job ! It hardly needed a clean but it got one anyway;  20220823_071814 20220823_071814 by dusty miller, on Flickr Before fitting the generator, you need to fit the woodruff key. It has a punched indent on one side that creates a tight fit in the groove on the crank, but a gentle tap will seat it. The generator will be in the way if you dont fit the woodruff key first though;  20220823_191959 20220823_191959 by dusty miller, on Flickr  20220823_195013 20220823_195013 by dusty miller, on Flickr Not sure what to do regards the idler gear. I know they are a bit baggy as standard, but I would like to reduce the slop a bit if I can;  20220823_200513 20220823_200513 by dusty miller, on Flickr Anybody done any sort of modification to improve this ? Cheers Dusty  |

|

|

|

Post by midlifecrisisrd on Aug 24, 2022 17:48:23 GMT 1

Does Rob not offer a rebushing service?

Someone did do a needle bearing I think

Steve

|

|

|

|

Post by dusty350 on Aug 24, 2022 17:58:55 GMT 1

Hi Steve I've spoken to Rob, and sadly not an option. It seems the shaft my be undersized for the idler bush to achieve a better fit, so even a new, standard bush may be baggy. Norbo sells an aftermarket gear with a roller bearing fitted - I dont think it's possible to fit a bearing to the existing gear due to the hole dimensions. I know there needs to some clearance but it does seem excessive. Dusty  |

|

|

|

Post by midlifecrisisrd on Aug 24, 2022 18:17:57 GMT 1

As long as it can't come into contact with the basket gear it may be baggy but won't cause any issues

At least on a ypvs the shaft is still available

With a new circlip and thrust washer it may be better

Steve

|

|

|

|

Post by dusty350 on Aug 24, 2022 20:09:39 GMT 1

It's probably the same as all the others I have had, but if I can improve it I will. Yamark has been in touch - he has a spare gear that Rob rebushed for him some time back, so I am gonna try that and see if it's better  Dusty  |

|

|

|

Post by JonW on Aug 25, 2022 14:20:44 GMT 1

New washer and clip as Steve says will help along with a new bearing (or whole new idler), you can fit a thicker washer to help take up slack as well.

FWIW Ive taken to buying new idlers these days, sure the shafts wear but with new fixings and new idler you at least stand a chance it wont rattle as bad.

|

|

|

|

Post by midlifecrisisrd on Aug 25, 2022 16:50:53 GMT 1

Really speaking the majority of the wear should be on the bronze bush and not the shaft

The other thing to remember is that when the gear is being driven it should run straight due to the load pushing it against the shaft

It needs to wobble to assist the engagement of the kickstart gear

I've got 4 of them in my basket waiting on a discount code and nicely got a 15% off code this morning 😏

Steve

|

|

|

|

Post by dusty350 on Aug 25, 2022 20:41:47 GMT 1

I know they need some play, plus too tight would be an issue too, but this one did seem more wobbly than usual. Popped over to see Mark today as he had a spare that was rebushed by Rob some time back;  20220825_200427 20220825_200427 by dusty miller, on Flickr Much better when trial fitted, and not tight. Cheers Mark, you are a star  Dusty  |

|

|

|

Post by dusty350 on Sept 3, 2022 7:48:16 GMT 1

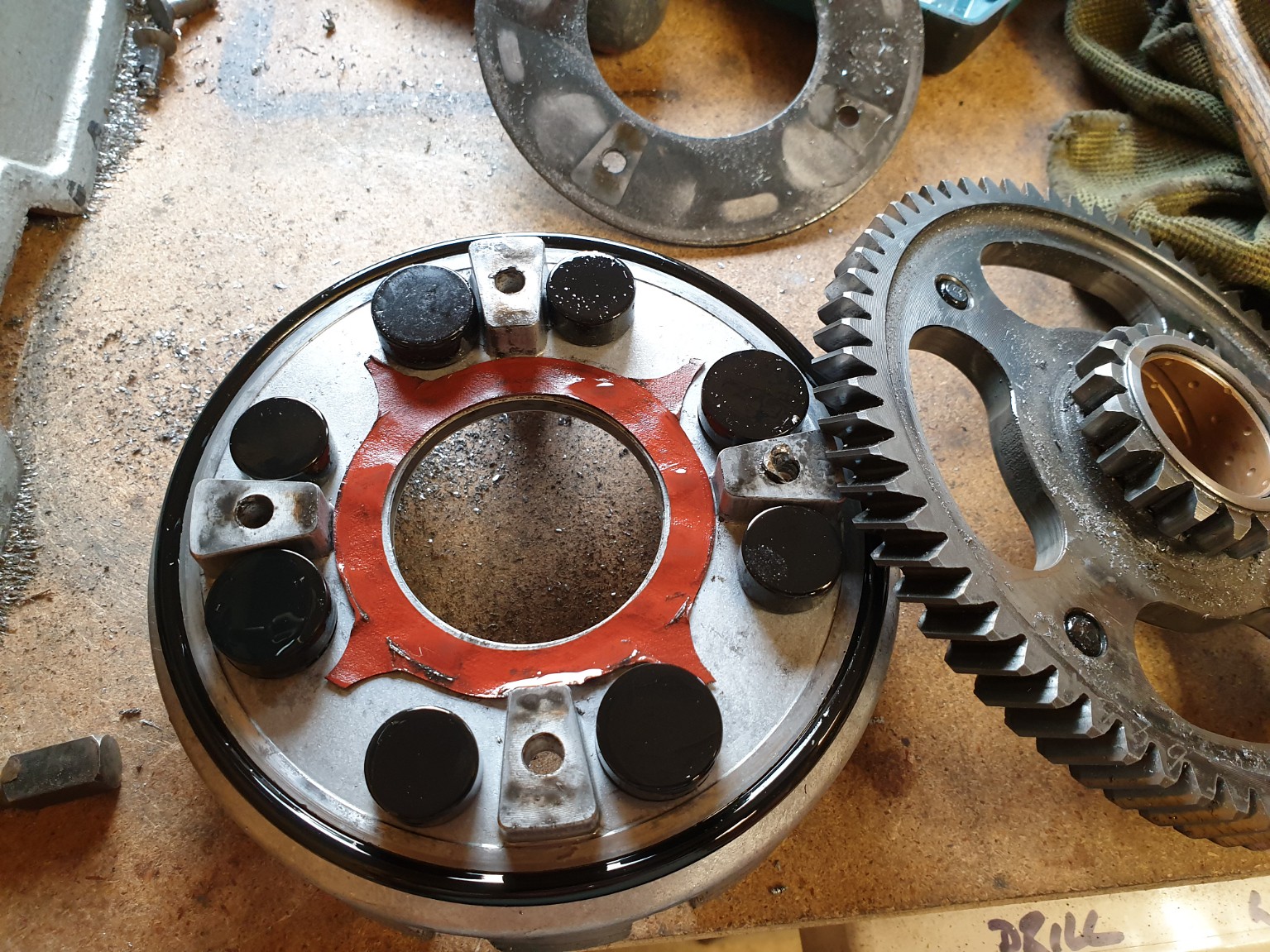

The postal strike has slowed up delivery of some parts, so whilst I am waiting, I thought I would strip the clutch basket. Some of the clutch "fingers" were heavily grooved in places, whilst others had obviously been filed down. There was a bit more rotational play than I would have liked between the driven gear and the basket too, so I bought a new Mitaka basket and rubber damper "pucks" from Norbo, and set to;  20220825_181902 20220825_181902 by dusty miller, on Flickr 4 rivets hold the basket assembly together. I centre punch and drill the ends off on my pillar drill;  20220825_182344 20220825_182344 by dusty miller, on Flickr With the rivet ends drilled off, you simply knock the rivets through, and the hardened back plate can be removed to reveal the dampers;  20220825_190955 20220825_190955 by dusty miller, on Flickr The driven gear now lifts off;  20220825_191025 20220825_191025 by dusty miller, on Flickr Interesting to note this basket has the round "pucks", with 4 large and 4 smaller. Other Lc baskets I've stripped in the past have had the "D" shaped pucks. This engine is a later number, so I think Yamaha must have swapped to the round pucks on later bikes. You can see the red gasket has all but disappeared. This gasket sits between the gear and the ali basket, and is there due to the rotational "play" between the gear and the basket. It's not available as a separate part from Yamaha as they only sell the clutch as a complete unit. Forum member "Rolie" did some research and had some new gaskets made. I contacted him and he had 2 left, which he is kindly sending to me (thanks mate - top fella  ) so once the gasket arrives I can rebuild the basket. Dusty  |

|

|

|

Post by dusty350 on Sept 3, 2022 20:39:39 GMT 1

Nothing from the postie today, so I thought I would prepare the cylinder head. I had stripped the manky paint off it some time back, and polished the rib around the edge. Last week I dropped it into Jamie so he could Cerakote it for me. Top fella that he is, he masked the rib with a thin heat proof tape before vapour blasting, then applied new tape for the Cerakote process. Really happy with the result;  20220903_192015 20220903_192015 by dusty miller, on Flickr I had also cleaned up the top housing and rear hose union as they were rough, and polished them up. Been sat on the bench for ages, so fitted them today with new stainless bolts, polished obviously !;  20220903_192049 20220903_192049 by dusty miller, on Flickr Fitted with new Yam gaskets;  20220903_192206 20220903_192206 by dusty miller, on Flickr  20220903_193402 20220903_193402 by dusty miller, on Flickr  20220903_194402 20220903_194402 by dusty miller, on Flickr I was undecided on what combination to have on the top end. I usually go with vapour blasted barrels and a painted head. My barrels arrived back from Paul at PJME after he had resleeved them for me, and I thought I would polish the rib on them to match the head. Once I got started I got a bit carried away, and decided to go with a polished finish - a first for me - and I think they look ok with the Cerakoted head;  20220831_185117 20220831_185117 by dusty miller, on Flickr More on the barrels later. Paul has done a fantastic job of the resleeving, and I'm now back to a standard sized bore, having been at 2.25 previously. I plan to do a separate thread on the resleeving process with pics and info kindly supplied by Paul. Dusty  |

|

|

|

Post by andy748 on Sept 3, 2022 20:55:34 GMT 1

Jesus Dusty, how long did it take to polish the barrels! Lovely job on the rebuild. Andy.

|

|

|

|

Post by dusty350 on Sept 3, 2022 21:06:03 GMT 1

Hi Andy, About an hour each. It helped that Paul had vapour blasted them when he resleeved them. I haven't tried to get them mirror polished all over - that would take forever, and would be nigh on impossible with my diy setup, plus I really need new mops coz all mine are worn out now. I aimed for a decent, smooth finish on the outside face, and then just buffed the rest up fairly lightly. I planned that if I didnt like it I would get Jamie to Cerakote them but now the head is back, I think I will keep them as they are. Plus it saves some cash not having to get them painted. I wanted to do something different to what I've done before too, and I've never polished barrels, so it ticks that box too  Dusty  |

|