|

|

Post by jon on Jun 11, 2016 21:57:35 GMT 1

After building my first LC hybrid, I thought a YPVS was on the cards, so I started on my 'Yamaha Hybrid #2' build. I saw a project LC for sale, and got to to thinking they are getting thin on the ground, so decided to ask about it. After a 440 mile round trip in a day, I had the makings of another hybrid. I've been collecting parts for a while now, and now it's time to start work on it (between my other projects).   Jon |

|

|

|

Post by unrealedd on Jun 12, 2016 11:28:24 GMT 1

You do like to keep yourself busy, what's on the cards for this one or is it strictly top secret?

|

|

|

|

Post by jon on Jun 12, 2016 17:55:03 GMT 1

Hi Edd, it's not top secret, it's just I can never decide myself and stick to it.

I'd been collecting a few parts to 'improve' my original LC hybrid, but will very probably bolt them on this one, and leave my original build as is.

I've got a lovely set of forks off a 4HW. Upside down, chrome, and twin disc. Bonus is they are exactly the same length as an LC.

I've got spare YPVS engines, and a load of nice wheels including FZR400RR rears which would look great on an OTT LC.

Time will tell, there is no solid plan yet.

Jon

|

|

|

|

Post by jon on Jul 12, 2016 20:58:00 GMT 1

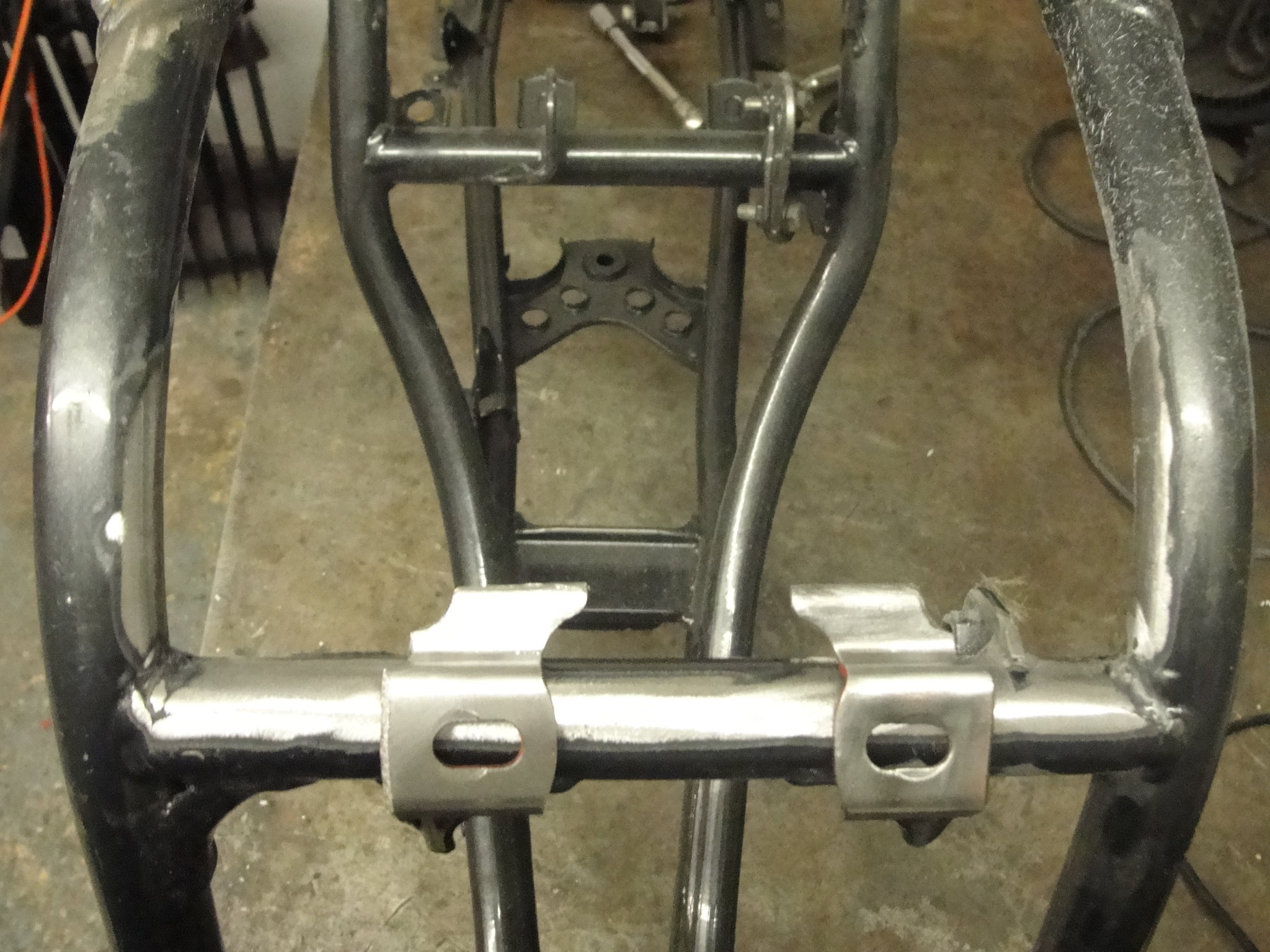

I'm really struggling on which direction this LC will take. I can't decide whether to spread the frame or not to take an OTT wheel (for an LC). I have 2 x 3TJ wheels at J4.5" x 17" which I'd like to fit one of them to this bike. Isn't this the same width as some RGV wheels, where the chain just clears the frame? Anyway, either way it will have a centre stand. The existing brackets had be cut off so needed replacing. Mark (Yamark) very kindly sent me the brackets from his epic triple build. I cut the old ones off and made a jig to ensure they were square.  I then tacked them in place to weld fully later if I decide not to spread the frame.  6 Centre Stand Bracket tacked on 6 Centre Stand Bracket tacked on by Jon Leech, on Flickr Jon |

|

|

|

Post by jon on Sept 2, 2016 20:09:30 GMT 1

I have the least direction on this bike than the other 2. However some things need doing whatever the final decisions. The sidestand bracket had obviously unattached itself from the frame at one point, and it had been 'welded' back on with the worst pockets of air voids and spatter I've seen for some time. Not only that it was at the wrong angle!  After cutting it off, dressing both parts, and checking the angle on my mate Geoff's frame we tack welded it on. I later welded it on fully at home.  Next step was some tie bar mounts as this was an 1980 frame. After dressing:  Then welding on:  I've been contemplating what's involved with spreading this frame, and will make an internal skeleton which bolts on a few mounting points this weekend to keep everything in line before cutting the frame to spread it. Jon |

|

|

|

Post by LC_BOTT on Sept 3, 2016 21:36:39 GMT 1

Good info, keep the pics coming as I've never been sure what to do when 'spreading' the frame, might need to do one myself, but really have no idea  so watching with interest. |

|

|

|

Post by jon on Nov 20, 2016 20:05:08 GMT 1

I've been busy between my 3 projects so progress is slow on each. However the last 2 weekends I managed to make this:  Jon |

|

|

|

Post by stusco on Nov 20, 2016 20:15:26 GMT 1

Give us a clue?

|

|

|

|

Post by jon on Nov 21, 2016 9:02:09 GMT 1

The clue is already there stusco.

Jon

|

|

|

|

Post by 4l04ever on Nov 21, 2016 14:45:56 GMT 1

It's a jig, but not an Irish one.....

|

|

|

|

Post by stusco on Nov 21, 2016 17:02:57 GMT 1

The clue is already there stusco. Jon Yeah but I need another one |

|

|

|

Post by Tobyjugs on Nov 21, 2016 18:30:00 GMT 1

I thought it was a scorpion and you still need to make his pincers  |

|

|

|

Post by jon on Nov 21, 2016 22:36:46 GMT 1

It's an endoskeleton (jig as you rightly say 4LO4ever). I'm in a Jekyll and Hyde moment at present as to whether to spread the frame or not, although I know I'm going to do it; It's just a shame that LC's are getting rarer.  Jon |

|

|

|

Post by yamark on Nov 23, 2016 7:48:01 GMT 1

Superb Jon, if you go ahead and spread the frame, let me know if you need any details on where the cuts are made. I'm pretty sure you'll not need my input  . . My frame was widened by 20mm in total. Spread too wide and the side panels start to get closer to the tank as they tip inwards!

Good luck with it  |

|

|

|

Post by jon on Nov 29, 2016 20:38:52 GMT 1

Thanks Mark,

I'd be interested to see where your cuts were made in your frame if you have photos you'd care to PM?

Failing that, I think I've worked out where and what I'm going to cut.

Difficult to explain what I have in mind, but I might post photos of the spread to show others how I did it.

All set for this weekend (wish me luck). The sooner it's done now the better, as there will be no going back.

Jon

|

|

|

|

Post by yamark on Nov 29, 2016 22:02:35 GMT 1

Thanks Mark, I'd be interested to see where your cuts were made in your frame if you have photos you'd care to PM? Failing that, I think I've worked out where and what I'm going to cut. Difficult to explain what I have in mind, but I might post photos of the spread to show others how I did it. All set for this weekend (wish me luck). The sooner it's done now the better, as there will be no going back. Jon I'll PM you Jon with details. The cuts were made on my frame where Harry said to make them. I understand he has spread several frames.

With your skill you will not need any luck

|

|

|

|

Post by jakethepeg007 on Nov 29, 2016 23:17:47 GMT 1

Pity your not closer, could of had a practice on my un-numbered frame

|

|

|

|

Post by jon on Dec 11, 2016 18:22:23 GMT 1

Well I've finally plucked up the courage to chop a perfectly good frame up. I had intended to do it last weekend, but bottled out. This weekend my brother in law put it into context by saying 'what you worried about? it's only an old bike frame'.  No turning back now. Jon |

|

|

|

Post by jon on Dec 29, 2016 18:44:39 GMT 1

On Advice from Jonw, and my better judgement; I am holding off welding up the final width of this frame, until I decide on a swingarm.

Initially I was going to go for YPVS dimensions, and adapt the swingarm to suit. It makes more sense to adjust both to suit in the best way.

I have read online that the swingarm I'm thinking about is 222mm on the pivot width. This seems more than enough to get 'good' chain frame clearance when using a 160 tyre.

I have to admit I've spread the frame little to see how it feels to do it. I've spread it from 201mm to 212mm to see how it reacted.

Jon

|

|

|

|

Post by Tobyjugs on Dec 29, 2016 22:42:55 GMT 1

Hi Jon how are you going to spread thre frame? with heat or cold and jack it.

|

|

|

|

Post by jon on Dec 30, 2016 11:11:52 GMT 1

Tobyjugs, so far I have spread it cold. Once the two cross members are out it's quite unsupported and easy to bend out with a bottle jack.

At first it sprung back to standard width after putting a little force on the jack. You have to over jack it wider than you want and then it springs partially back.

I will try a little heat if needed with it under pressure when I go for the finished width, but to be fair it probably doesn't need it from the feel of it.

Once I put the jig back in to check for even spread either side, if one side is bent more than the other I may apply heat to the stronger side to get it to bend before the other. However at present it's bending evenly.

Jon

|

|

|

|

Post by jon on Jan 15, 2017 10:51:17 GMT 1

My swingarm arrived, so it was time to spread to the final width. I've gone for a braced FZR arm.  I did it a bit at a time and kept swapping the bottle jack over from side to side, but to my relief it spread really evenly both sides. I bolted the jig back in to check, and then was around 11mm both sides.  I turned up a couple of spacers to use either side of the jig around the swingarm pivot, so it is all held together before welding the cross members back in.  Jon |

|

|

|

Post by Tobyjugs on Jan 15, 2017 11:46:11 GMT 1

NIce one jon, i like the style of the swing arm as well. When your finished you will have special tools for hire  |

|

|

|

Post by oldelsieboy on Jan 15, 2017 12:05:00 GMT 1

Nice one jon, I like the style of the swing arm as well. So do I   OEB |

|

|

|

Post by jon on Jan 15, 2017 19:41:17 GMT 1

I got time to make the reducers/spacers for the rear engine mount cross member today. It needed widening by approximately 11mm either side. I turned down some spacers, and then ground a scollop in then with a die grinder.  These will be welded onto the cross member and ground back, before welding the cross member in with it bolted to the jig.  Jon |

|

raggy

L plate rider.

Posts: 49

|

Post by raggy on Jan 15, 2017 22:14:19 GMT 1

Great project, just curious, how will the chain alignment be affected/

|

|

|

|

Post by JonW on Jan 16, 2017 0:18:22 GMT 1

Wonderful work Jon.

|

|

|

|

Post by yamark on Jan 16, 2017 22:03:51 GMT 1

Very nice Jon - you've got to be pleased with that. Did the swingarm plates stay parallel? Looks like they did  |

|

|

|

Post by jon on Jan 18, 2017 0:50:08 GMT 1

Thanks Yamark and Jonw for the appreciation.

Raggy, the chain alignment IS the reason for spreading the frame. I plan to use a 160 rear tyre on the 3TJ rim.

As the frame tubes are around 201mm at the swingarm, that means around 20.5mm for the chain to run in if aligned properly.

As a 520 chain is around 18.5mm wide that means it would have around 1mm clearance either side before sawing into the tyre or frame.

By widening by 22mm you get around 6.5mm between the frame and tyre.

Jon

|

|

|

|

Post by jon on Jan 24, 2017 22:40:46 GMT 1

The centre stand cross member tube was slightly bent. I took this opportunity to replace it with a thicker walled tube.  Spreading is done, and all welded up. Next will be the strengthening.  Although subtle, you can see the width increase from standard.  Jon |

|