|

|

Post by Tobyjugs on Apr 6, 2018 16:32:33 GMT 1

Hi Steve i have 71 PK coming out my other engine and that is currently using 490 main jets and standard carbs. This engine is around the 65 PK so i did expect the carbs to be sufficient. The carbs were sufficient until i put the modded reeds and air intake on then it all went lean.

I also want to keep small carbs on the bike as well.

I have just measured the fuel level against the bowls. Both levels are the same but the carbs are slightly slanted so measured from the middle section of the carb. I had set the 21mm float height with the gasket in place. i have now set them at 20mm with no gasket in place.This means i have raised the fuel level 2mm from my original setting.

|

|

|

|

Post by midlifecrisisrd on Apr 6, 2018 18:26:00 GMT 1

They are supposed to be measured without the gasket so may be the issue

Steve

|

|

|

|

Post by Tobyjugs on Apr 6, 2018 19:39:22 GMT 1

Just come back from doing a few rides, theres not much change. i will put it all back to standard and try to get some PWK's

|

|

|

|

Post by Tobyjugs on Apr 7, 2018 9:23:46 GMT 1

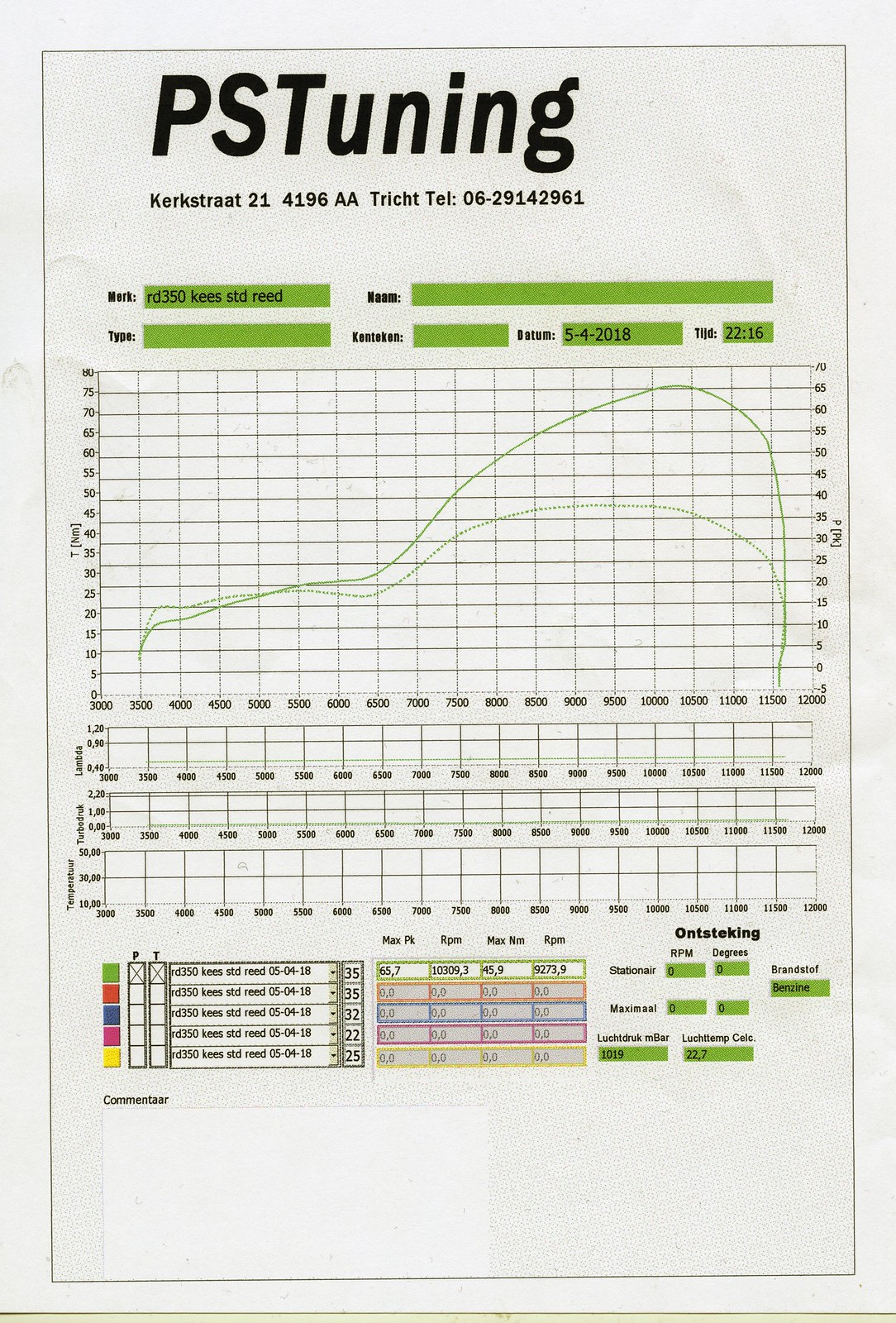

I was going to put a few graphs up so you could see what was happening as i changed the intake parts but they never got saved so i only have this one run which i think was the first run, running slightly lean.  Standard reeds TSA road pipes Standard Chariot intake manifold 460 main jets 345 P0 needle jet 27.5 pilot jets |

|

|

|

Post by Tobyjugs on Nov 15, 2018 22:59:53 GMT 1

I thought it might be easier to just open this thread up again for Earthman.

Hi Earthman the dyno chart for closed piston versus piston with windows is on the bottom of page 1

|

|

|

|

Post by Tobyjugs on Feb 10, 2019 14:29:42 GMT 1

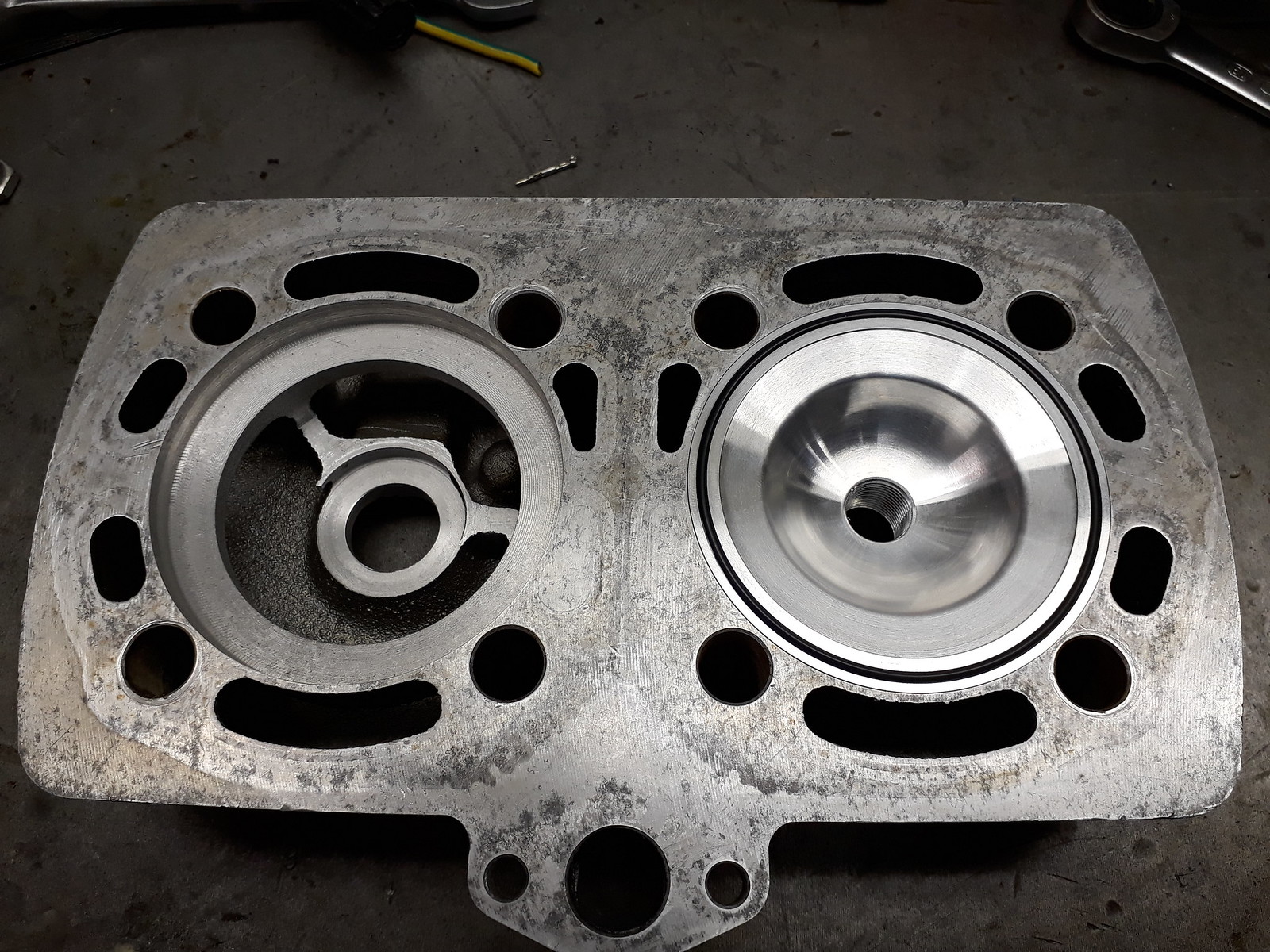

Just to recap on this thread. I made a cylinder head that has removable domes and i copied the idea of the cool head which allows more cooling water to flow over the combustion domes and less to flow around the liners and exhaust manifold. When i open up the engine for a inspection i was surprised to find a brown lacquer forming on the running surface of the liner. Also the difference in the cooling water in and out was too small to measure at higher rpm. Below you can clearly see the lacquer formation from using the Cool Head principle. The lacquer had to be removed by hand with Scotch Brite.  Below is the same engine using a standard cylinder head with the standard cooling water flow path. You can see it is much better. The oil and fuel that is used has always been the same.  My removable dome head has now been modified to use the original flow path from Yamaha.  The bike has been driven around and i have noticed a bigger difference in the temperature in and out the engine. This is a good sign. Next step is to dyno test it. |

|

|

|

Post by mick858 on Feb 10, 2019 17:41:55 GMT 1

I think you need to rename this thread as you clearly do not need any help from the tuning gurus.

|

|

|

|

Post by Tobyjugs on Feb 10, 2019 18:25:16 GMT 1

I think you need to rename this thread as you clearly do not need any help from the tuning gurus. Ha Ha this thread is long and old and lots of help or advice has come from members of this site and of course the tuner from PS Tuning. |

|

|

|

Post by marrcel on Feb 10, 2019 22:10:32 GMT 1

I think you need to rename this thread as you clearly do not need any help from the tuning gurus. Ha Ha this thread is long and old and lots of help or advice has come from members of this site and of course the tuner from PS Tuning. I saw a picture of you and Pieter in the Motoplus Magazine. It was an article about the dirt track @ Rotterdam. 👍 |

|

|

|

Post by marrcel on Feb 10, 2019 22:29:07 GMT 1

Good info Tony👍

I am interested in the fluid dynamics. The laquer is a sign of too hot. So the flow at the barrel was to low. And the head was cool but the barrel not. So which restrictions distribute both the flows around the head and the barrels.

Did you gave the cool head more restiction so there the barrel got more cooland flow?

Can you tell us more about were you modified the restrictions?

|

|

|

|

Post by Tobyjugs on Feb 10, 2019 23:54:41 GMT 1

Ha Ha this thread is long and old and lots of help or advice has come from members of this site and of course the tuner from PS Tuning. I saw a picture of you and Pieter in the Motoplus Magazine. It was an article about the dirt track @ Rotterdam. 👍 I was also surprised that we made it into the magazine. The pictures above are from the engine that Kees Doelman used to reach 3rd place in the sprint event. We had two bikes and were with the three of us. The little RD's surprised a lot of people and were a favourite with the crowd due to their underdog status and knocking out a lot of large cc bikes  Kees also made it into the Big Twin magazine which i thought was funny. |

|

|

|

Post by Tobyjugs on Feb 11, 2019 0:19:07 GMT 1

Good info Tony👍 I am interested in the fluid dynamics. The laquer is a sign of too hot. So the flow at the barrel was to low. And the head was cool but the barrel not. So which restrictions distribute both the flows around the head and the barrels. Did you gave the cool head more restiction so there the barrel got more cooland flow? Can you tell us more about were you modified the restrictions? Basically i tried to copy a cool head by leaving a small area open which short circuits the coolant over the head. I have converted it back to standard by filling in the two cut out areas with liquid metal. In the picture you can see clearly the metal removed from the casting that separates the in and out flow of the cooling fluid.  In the picture below you can clearly see the separating part of the casting built up with liquid metal. The back side of the combustion dome is round and the liquid metal sits flush against the dome.  below you can clearly see the back of the combustion dome.  Once i know this is working ok i will try to O-ring the outside of the cylinder head and also the long nuts which also go through the cylinder head. The idea is to make a multi purpose cylinder head which could be used for all the other ideas i have rattling around in my head whether it be a 250 or a larger cc engine you will only have to fit a dome to suit the characteristics of the engine. I am no longer a fan of the cool head idea. |

|

|

|

Post by Tobyjugs on Feb 23, 2019 21:04:55 GMT 1

Ok back to the story.

The prototype cylinder head is now refitted with a squish height of 0.90 mm and a compression ratio of 12.5:1. Previously it was fitted with a standard head and OME gasket with approximately 2 mm squish height and a much lower compression ratio which i forgot to note.

Unfortunately i do not have any nice pictures for you as i was a little busy trying to sort out the jetting.

I thought that if i only changed the compression ratio of the cylinder head it would need only a small tweek in the jetting. How wrong i was.

If i remember correctly with the standard head fitted the bike was making 63 hp safely.

After fitting the prototype cylinder head i went for a test ride and was very happy the bike felt good and riding from low rpm rolling the throttle open the engine just picked up and revved out without any stutter or hesitation. I did not do any plug chops as i knew the next time it was started it would be on the dyno bank. I bimbled around a bit and went home. Out of interest i did remove one plug and it did look very dark brown and i thought it might be a bit too rich.

On the Dyno bank the bike was warmed up and a few runs were made it was sounded good and was making a nice line and was topping out at 68 HP The plug was checked and it was a very light tan colour which was showing it was too lean. Putting larger jets in cured this problem but it was then running very rich in the mid range section.

No matter what i did the it was a choice between lean top end and good mid range or good top end and very bad missfire in the mid range.

The needlles fitted were The JJH type. I have got some N68A needles but for got to take them with me.

Tomorrow i have been invited out for a ride and as long as i ride above 6500 rpm it behaves itself even though it wants to go into warp mode, but the cafe racer crowd tend to pootle along which means i will be driving an asthmatic Kangaroo. I might just be anti social and try those other needles.

Any one with needle expriance please join in and share your experiance.

|

|

|

|

Post by headcoats on Feb 23, 2019 21:23:43 GMT 1

What mains were the first ones and what did you go up to ?

|

|

|

|

Post by Tobyjugs on Feb 23, 2019 21:33:13 GMT 1

What mains were the first ones and what did you go up to ? I went from 155 up to 165 plus needle up and down and airscrew in and out. |

|

|

|

Post by headcoats on Feb 24, 2019 12:08:19 GMT 1

What pilots?

Muttsnuts uses big pilots as it seems on these carbs the pilot needles and mains really overlap each other

|

|

|

|

Post by Tobyjugs on Feb 24, 2019 15:55:35 GMT 1

What pilots? Muttsnuts uses big pilots as it seems on these carbs the pilot needles and mains really overlap each other That sounds about right. I have 50's in at the moment. That was one of the surprises i saw. I went from 48 to 50 and it showed the dyno read out jumped from 60 to 63 which really surprised me. It was about 2.5 PK difference. the N68A needles are fitted but because of the good weather plod is about due to all the extra bike activity. Not so good for doing plug chops. No hills here for resistance so you just have to drive faster and use the air resistance  |

|

|

|

Post by headcoats on Feb 24, 2019 17:33:08 GMT 1

Think we should start a seperate thread about PWK settings as it's interesting stuff !

I only have had 3 dyno runs on my YPVS motor and main jet was 152 with Ramairs and 42 pilots

I went up to 160 mains one run and lost 5bhp !

|

|

|

|

Post by Tobyjugs on Feb 24, 2019 20:53:50 GMT 1

I went out for a quick spin tonight and it felt better with the N68A needles. It started first kick with little choke and its cold so thats a sign that its a little rich where as before it was more lean. Blatting it through the gears you have no stuttering of flat spot and only in 5 and 6 if you open the throttle to full from 3000 rpm it then show a bit of the infamous 5-6k flat spot.

It sounds positive but i need to do some tests and plug chops to be realistic.

Does anyone Know if there are any other variants of the N68 type needles?

I could not find any emulsion tube info either only stories about fixed tubes being worn out?

|

|

|

|

Post by midlifecrisisrd on Feb 24, 2019 21:27:42 GMT 1

Ive always had the understanding that you need the N68 needle with pod folters to lean out the large main jet needed for top end

Airbox is jjh

Sure I have n68x needles

Steve

|

|

|

|

Post by Tobyjugs on Feb 24, 2019 23:16:01 GMT 1

Ive always had the understanding that you need the N68 needle with pod folters to lean out the large main jet needed for top end Airbox is jjh Sure I have n68x needles Steve Hi Steve i bought the N68A needles on your advice. It seems to be that the N series Needles have multiple tapers. There is not much to find on the internet. i would really like to know the difference between the A and X versie and i guess there must be a few more in between. |

|

|

|

Post by headcoats on Feb 25, 2019 9:04:55 GMT 1

|

|

|

|

Post by Tobyjugs on Mar 5, 2019 10:48:44 GMT 1

Thanks for the tip. If you google scooter with Keihin needles the N series does come up. Most seem to be after market so it does make me think are they worth it? I sent an email to the link you gave me and they responded very quickly telling me they could order more types of N needles but they have to wait as they come from Japan. then i told them i could not find many N needles that were original and asked then if their needles were original. The reply was we think they are but were not sure. They were however very quickly to reply to every e-mail. The chart below is for guidance (relevant to 28mm PWK carbs) N68B [Rich] N68C N68D N68E N68F N68G N68A [Standard] N68H N68I N68J N68K [Lean] Strange how they put the A-needle in the middle. I have also read a thread from Nick Fubar who used a N99 needle and also some comments on the N68X needle but could not find anyone selling them. |

|

|

|

Post by headcoats on Mar 5, 2019 11:09:13 GMT 1

If they are from Japan then that's a positive thing ?

They should know though if genuine or not ,shouldn't they?

|

|

|

|

Post by midlifecrisisrd on Mar 5, 2019 12:30:59 GMT 1

From memory the n99 needle only works with the 4.0 slide

Most have a 3.5 slide

Feck knows what the difference is

Steve

|

|

|

|

Post by Tobyjugs on Feb 26, 2020 13:54:52 GMT 1

Bump

|

|

|

|

Post by tsa on Feb 26, 2020 16:41:04 GMT 1

Dont get hung up on rpm when jetting its all related to throttle position. The slide position will relate to the circuit being used but remember 2 things there is always some overlap between circuits and the pilot jet flows all the time so adds fuel to all circuits not just idle.

|

|

|

|

Post by Tobyjugs on Feb 26, 2020 18:07:56 GMT 1

Yes Kenny I have always got the throttle marked into 1/2, 1/4, 1/8 increments so I can see what position the slide is in.

|

|

|

|

Post by Tobyjugs on Feb 26, 2020 18:10:52 GMT 1

I need to update this thread but I've been focusing on the Bakker project

|

|

|

|

Post by Tobyjugs on Jul 8, 2020 20:48:00 GMT 1

Bump for Flames

|

|