|

|

Post by billy on Feb 18, 2013 5:56:22 GMT 1

Sweet! I like your custom washers. Wish I had a lathe too, one day I'll get one.  |

|

|

|

Post by jon on Feb 25, 2013 20:43:03 GMT 1

|

|

|

|

Post by hardhatharry on Feb 25, 2013 21:05:04 GMT 1

Thats very shiny - where did you get the exhaust nuts from and what stops them vibrating off?

|

|

|

|

Post by jon on Feb 25, 2013 22:35:21 GMT 1

Physics Harry. In the 1950s+ Most exhaust nuts were brass for a very good reason. It expands quicker than steel and so increases the tightness.

In the 70s+ manufacturers started trying to save money. If an application did not require a more expensive material it was dropped. Amazing to save a few pennies, but that's mass production.

Today even some applications still use brass fittings for exhaust applications. Corsa for example.

Anyway, I have driven Lambrettas for nearly 30 years, and can honestly say even after a single journey of 300+ miles (where the main problem) is likely to be the exhaust, it was OK with brass exhaust nuts.

|

|

|

|

Post by bryan on Feb 26, 2013 18:41:51 GMT 1

They look like the same pipes I have from Gibson, but with Alloy end cans, is that correct. Going to changing mine from carbon to Alloy cans this year, as I think they will sound better.

What was it you used to clean the seat cover with, as I still need to do the one for the LC Im restoring, as it looks like it done a good job.

|

|

|

|

Post by jon on Feb 26, 2013 21:04:46 GMT 1

Sorry thought I was clear in my previous threads? ...

Harry, made the exhaust nuts myself.

Bryan, new seat cover fitted.

|

|

|

|

Post by jon on Feb 26, 2013 21:10:28 GMT 1

Bryan, sorry, forgot to say ... Yes your right they are Gibsons.

Back in the day a number of my friends had Allspeeds. I have to admit I had Microns.

I could not resist the heritage of Gibsons/Allspeeds when wanting new pipes for this project.

|

|

|

|

Post by bryan on Feb 26, 2013 22:02:15 GMT 1

Havent read you past posts. I'll have a look back

|

|

|

|

Post by jon on Apr 8, 2013 20:30:45 GMT 1

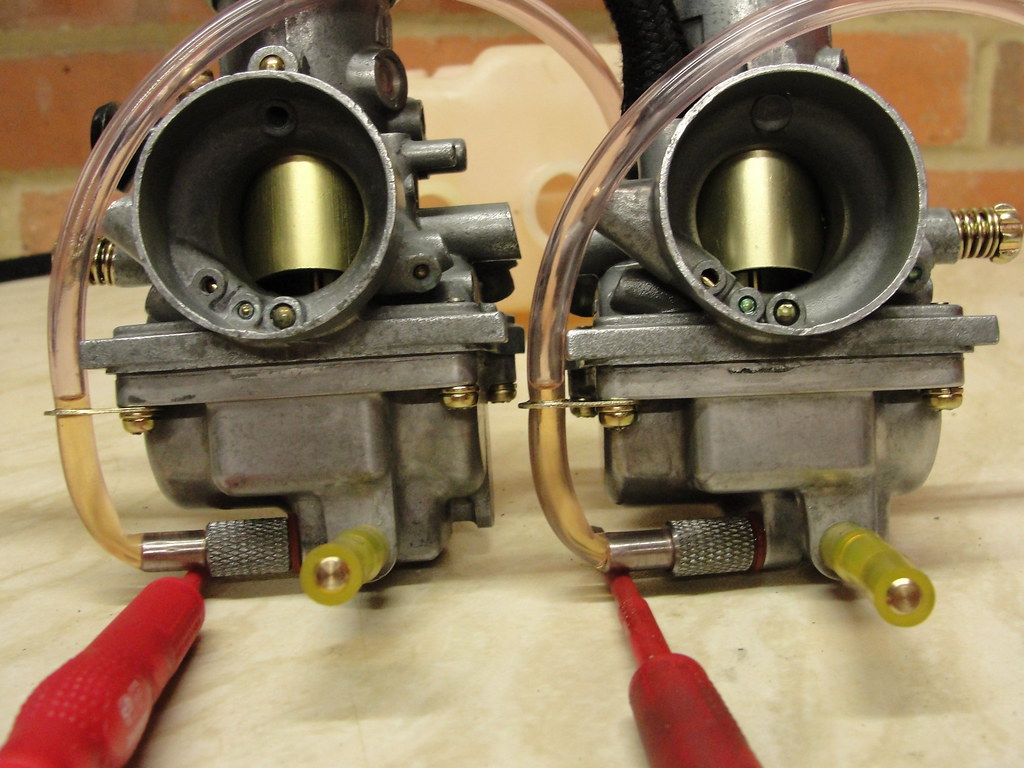

I’ve been doing loads of fiddly little things that seem to have taken ages. I have to admit I’ve got and bit side tracked. As the build has gone on I’ve made loads of changes from the original idea. I’ve ended up with a load of redundant bits (YPVS motors, FZR forks/disks/callipers, RGV swingarm etc). Surely it makes more sense to get even more parts to build another bike?  Anyway LC progress, Cleaned carbs and bits  Re-assembled carbs  |

|

matt7

Thrash Merchant

Smell of the 2 stroke & the roar of the crowd

Smell of the 2 stroke & the roar of the crowd

Posts: 445

|

Post by matt7 on Apr 8, 2013 20:51:15 GMT 1

Cool build, excellent skills & good write up  I like your Super7, very nice bit of kit. I looked at a Colchester Bantam at the weekend, am finding the limits of my little Emco (see Yamagamma thread) , lathes are frickin great things to have  Look forward to seeing more... |

|

|

|

Post by jon on Apr 9, 2013 19:56:32 GMT 1

Thanks matt7 for the positive comments. More very soon. I have loads of before shots, but not quite finished enough for after shots. Definately on the road for the sun (hoping) this year. I'm really with you on the lathe front being an engineer, but don't want to seem too enthusiastic as most people won't understand? Lathe forum? Maybe not yet ...  My lack of progress recently has been because of collecting parts for my next project. A YPVS. It now has a skeleton and matching heart, as well as all my other spares to perform a resurrection. |

|

|

|

Post by tigermac on Apr 27, 2013 10:43:12 GMT 1

Can't wait to see the outcome of this one!

|

|

|

|

Post by jon on Jun 2, 2013 19:03:27 GMT 1

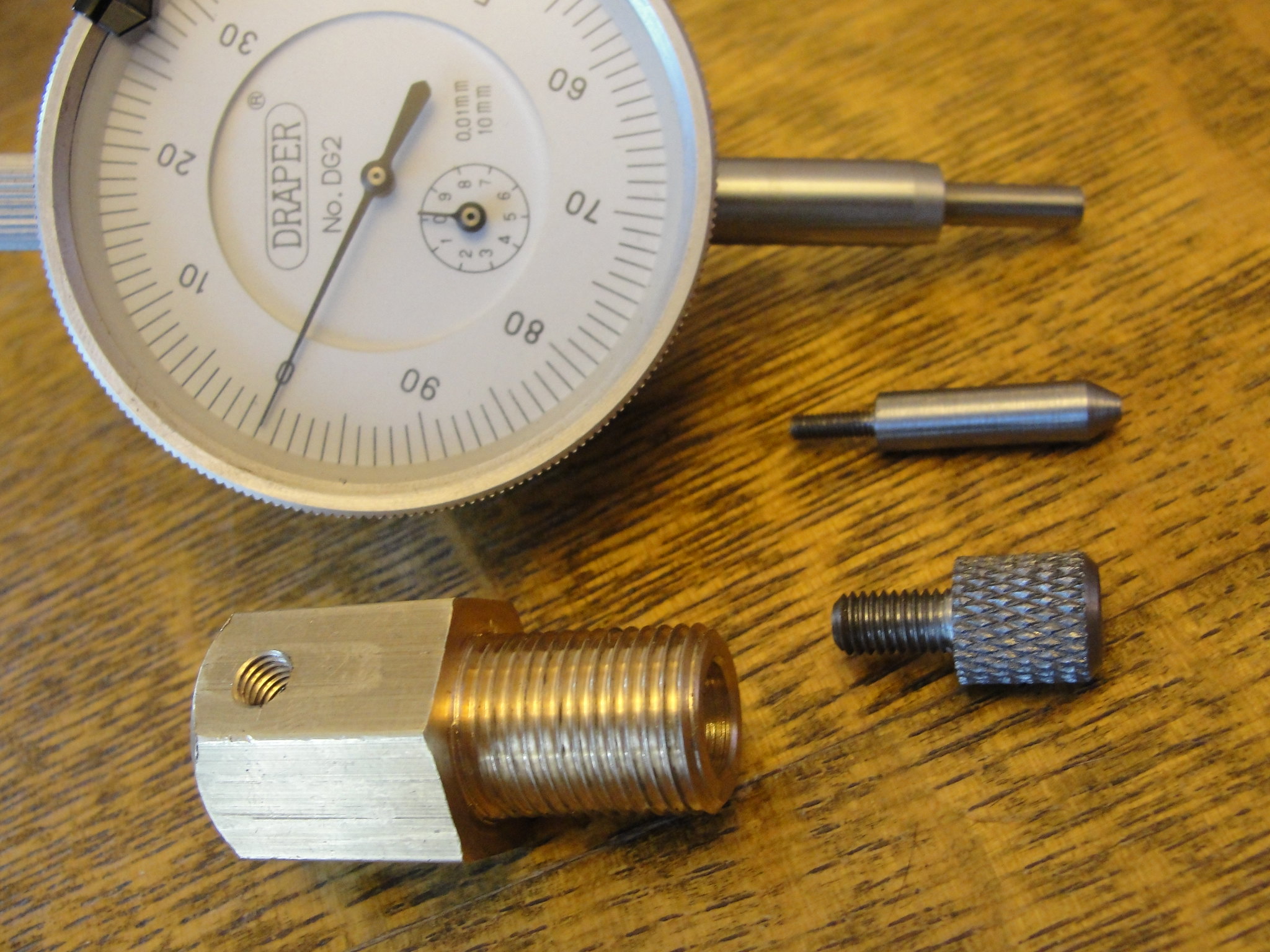

I'm quite pleased I've actually done loads of little bits this weekend that really have made headway to getting the bike finished. I've been wanting to bolt my side casings on for a while, but due to timing, and oil pump they have been off. I've set my timing to 1.8mm BTDC (modern fuel). To do this I first had to make a DTI adapter, as I could not find one on Ebay? Anyway I'm pleased with the result!   Got loads of spare metal to make others, so could potentially make some more if anyone is interested? |

|

|

|

Post by jon on Jun 8, 2013 19:14:24 GMT 1

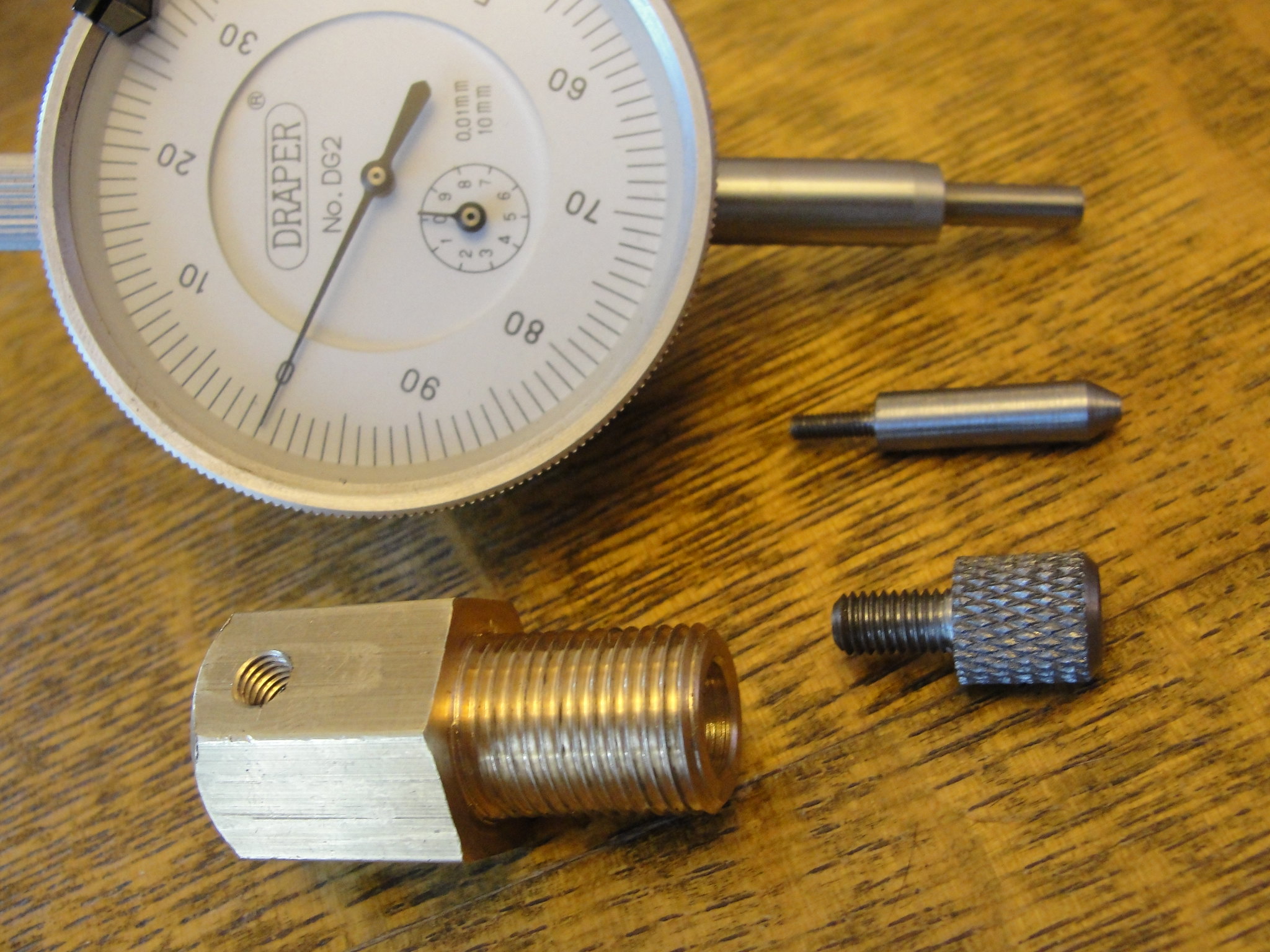

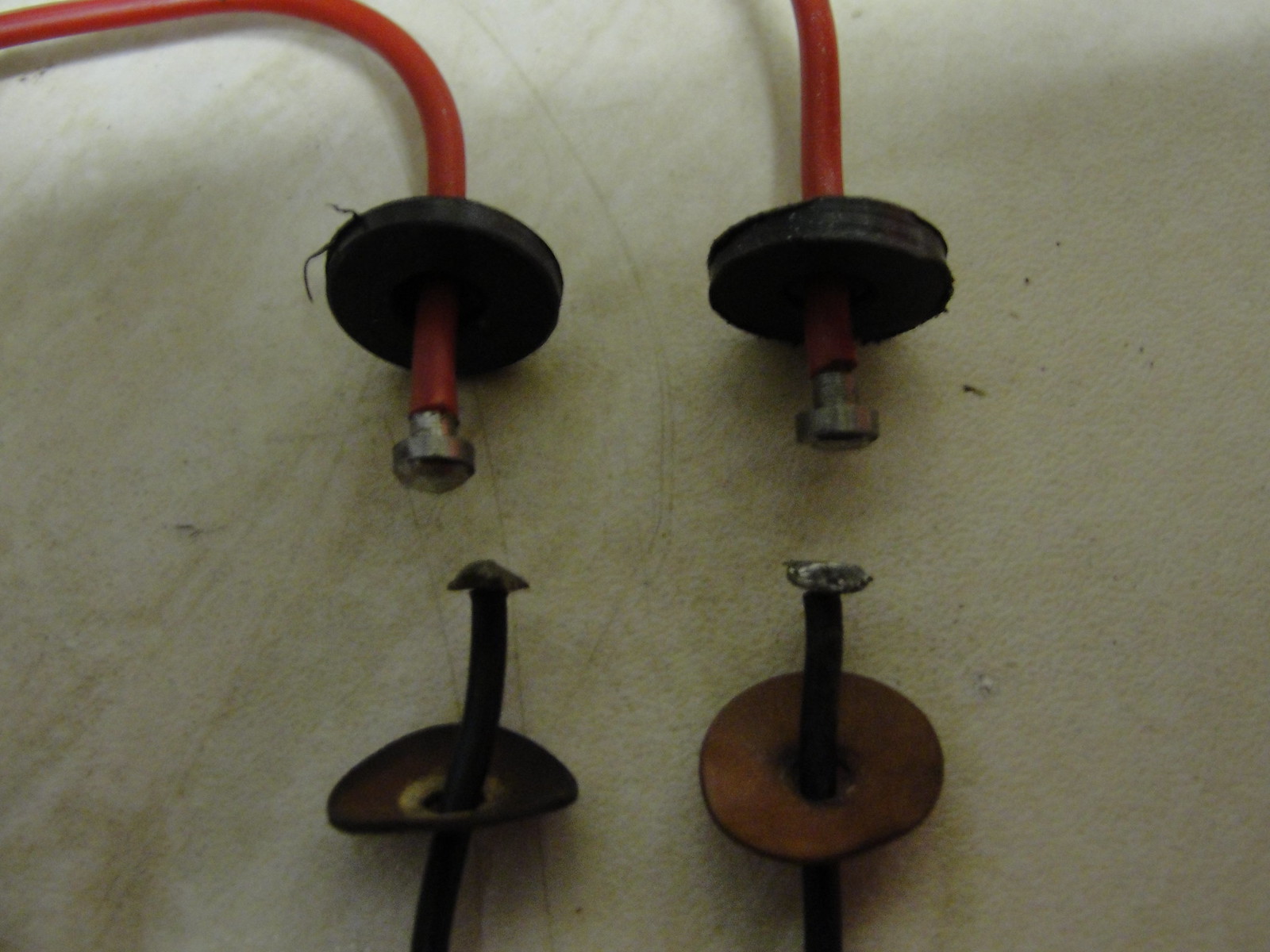

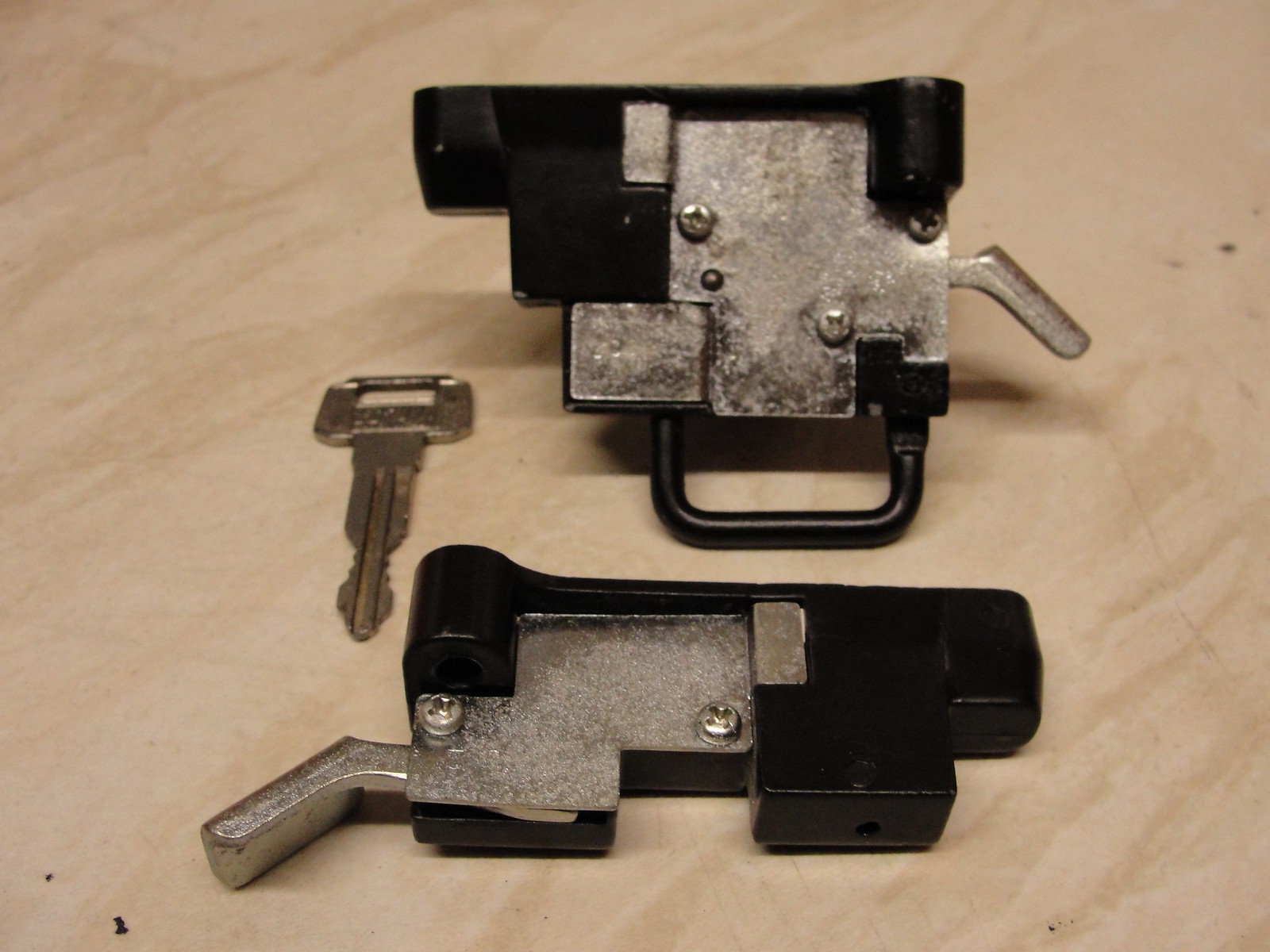

I can finally see I'll be firing up the LC soon. I need to get some finishing bits from Norbo, but they are mainly cosmetic. Anyway, today I rebuilt my switchgear after painting it. I painted it satin black, stuck on decals, then satin lacquered them. I'm glad I took photos on disassembly, they were really fiddly and took ages!   There was a tiny plastic bit broke in the switchgear. I looked for a bit of nylon, and found an old Vespa oil deflector; then shaped it as a replacement.  The indicators were pattern items, and a bit shoddy wiring, and the chrome paint only covered about 50% of the bowl! I made some new little nipples to solder on and insulators, and painted the bowls fully (new nipples top of photo, shoddy originals on bottom).   Took the seat locks apart to repaint and get the bits replated:    |

|

|

|

Post by littlebloke on Jun 17, 2013 16:48:42 GMT 1

fantastic work

|

|

|

|

Post by kennyroberts on Jul 1, 2013 22:53:18 GMT 1

Im loving the before and after shots. Its good to see how far you have come. And good to see how much work goes into each little bit.

Top quality work mate.its looking amazing

|

|

|

|

Post by jon on Jul 14, 2013 19:58:43 GMT 1

Managed to do a bit on the LC this weekend between tidying the garage and getting the Lambretta ready for an MOT and taking it. I'd bead blasted the master cylinders and rear calliper a while ago.  I then coated them in satin black, and polished off the raised letters, and followed with satin lacquer. Built them up today with new pistons and seals. I very pleased with the result.    |

|

|

|

Post by turbopresh on Jul 14, 2013 20:28:17 GMT 1

this thread is a bit dirty  |

|

|

|

Post by botty on Jul 16, 2013 23:22:32 GMT 1

Physics Harry. In the 1950s+ Most exhaust nuts were brass for a very good reason. It expands quicker than steel and so increases the tightness. In the 70s+ manufacturers started trying to save money. If an application did not require a more expensive material it was dropped. Amazing to save a few pennies, but that's mass production. Today even some applications still use brass fittings for exhaust applications. Corsa for example. Anyway, I have driven Lambrettas for nearly 30 years, and can honestly say even after a single journey of 300+ miles (where the main problem) is likely to be the exhaust, it was OK with brass exhaust nuts. Physics. That's it then. Brass nuts. Cos mine keep coming undone. |

|

|

|

Post by jon on Jul 17, 2013 8:02:19 GMT 1

botty I've no idea whether brass nuts will be enough for an LC yet as I haven't tried. However they cannot be any worse, and are still used occasionally today, I assume for difficult applications. My only experience of RDs was a YPVS I had 20 years ago, which I had for many years without this trouble. I did buy a new set of microns from Stan Stevens for it though. The slip joint design is much better. Has anyone tried lock wiring the nuts if they keep coming loose?

|

|

|

|

Post by jon on Aug 18, 2013 20:20:09 GMT 1

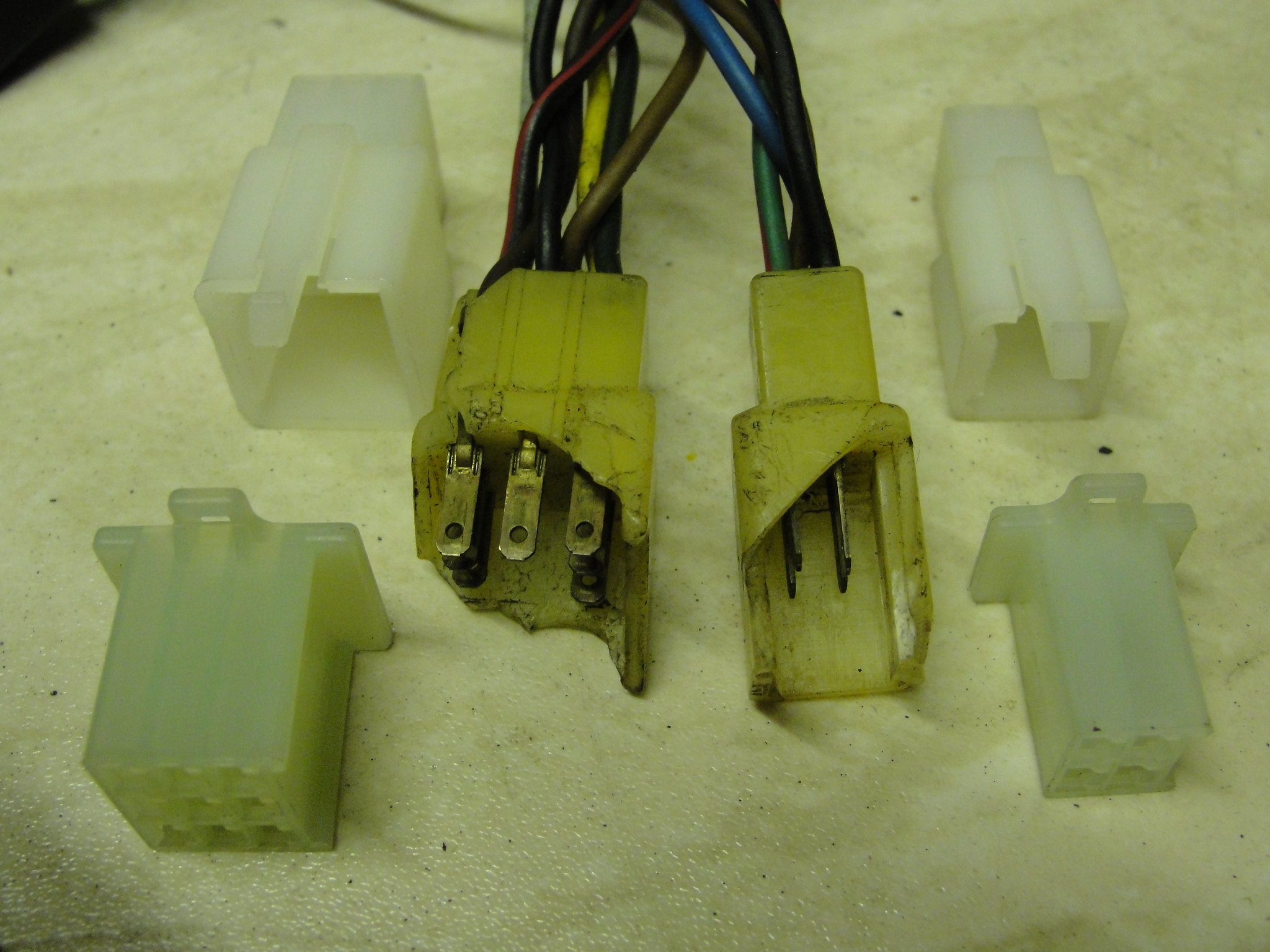

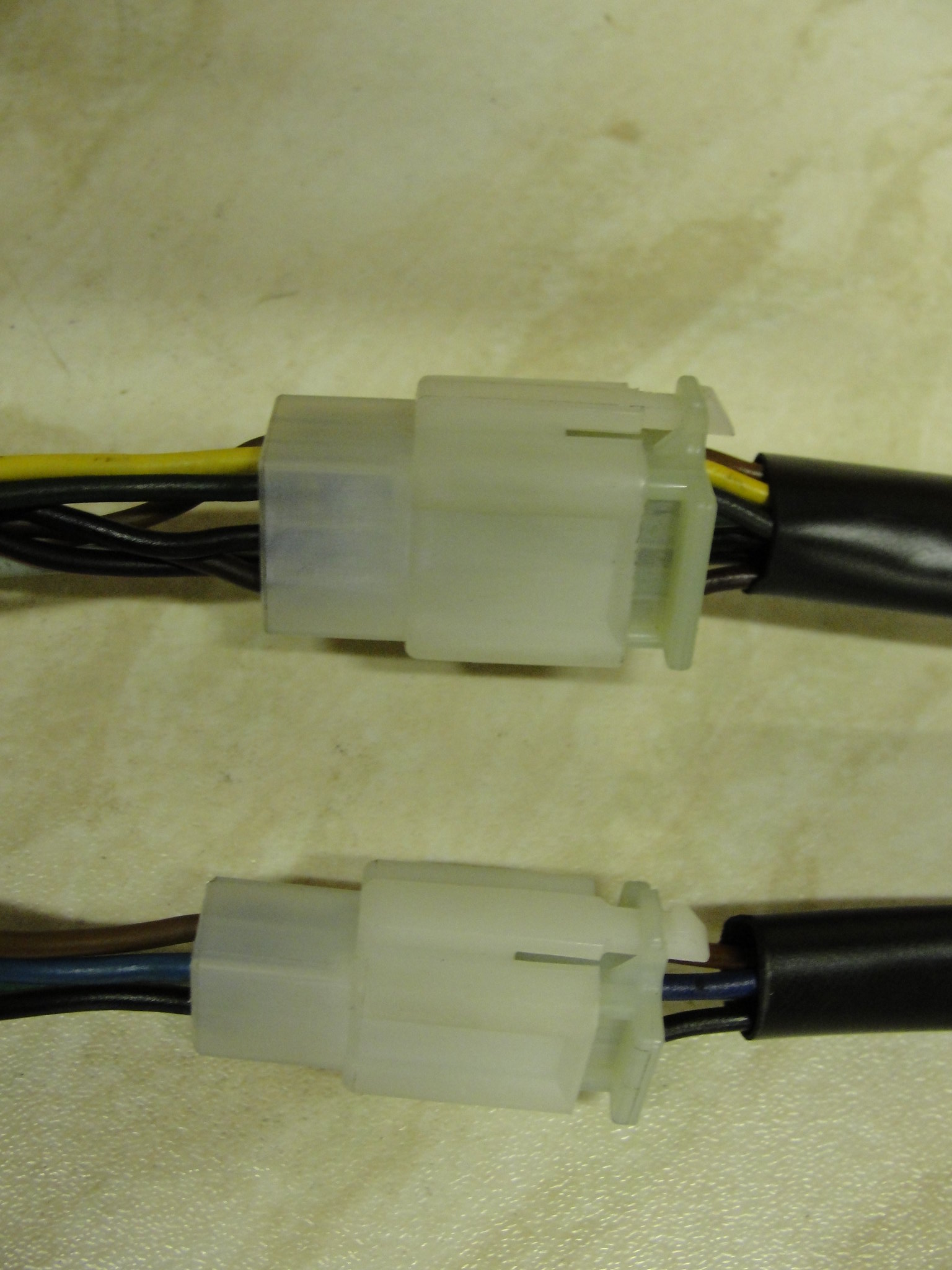

I have been plugging away (sic) at the LC over the last month, and have made some slow but worthwhile progress. My wiring loom had grubby connectors, and I wanted to fully clean every terminal. I used a combination of carb cleaner, WD40, cotton buds and a toothbrush. Really pleased with the results! Anyway two of the connectors had a broken plastic outer.  So I got new multi-connectors to replace them with. Good thing is they are actually same size as original!  |

|

|

|

Post by jon on Aug 18, 2013 20:24:04 GMT 1

I've also been busy repairing the original throttle cable. I looked at the Venhill website, but could not find the exact sizes for an LC; and so spent 4 hours machining the nipples!  |

|

|

|

Post by jon on Aug 24, 2013 20:58:58 GMT 1

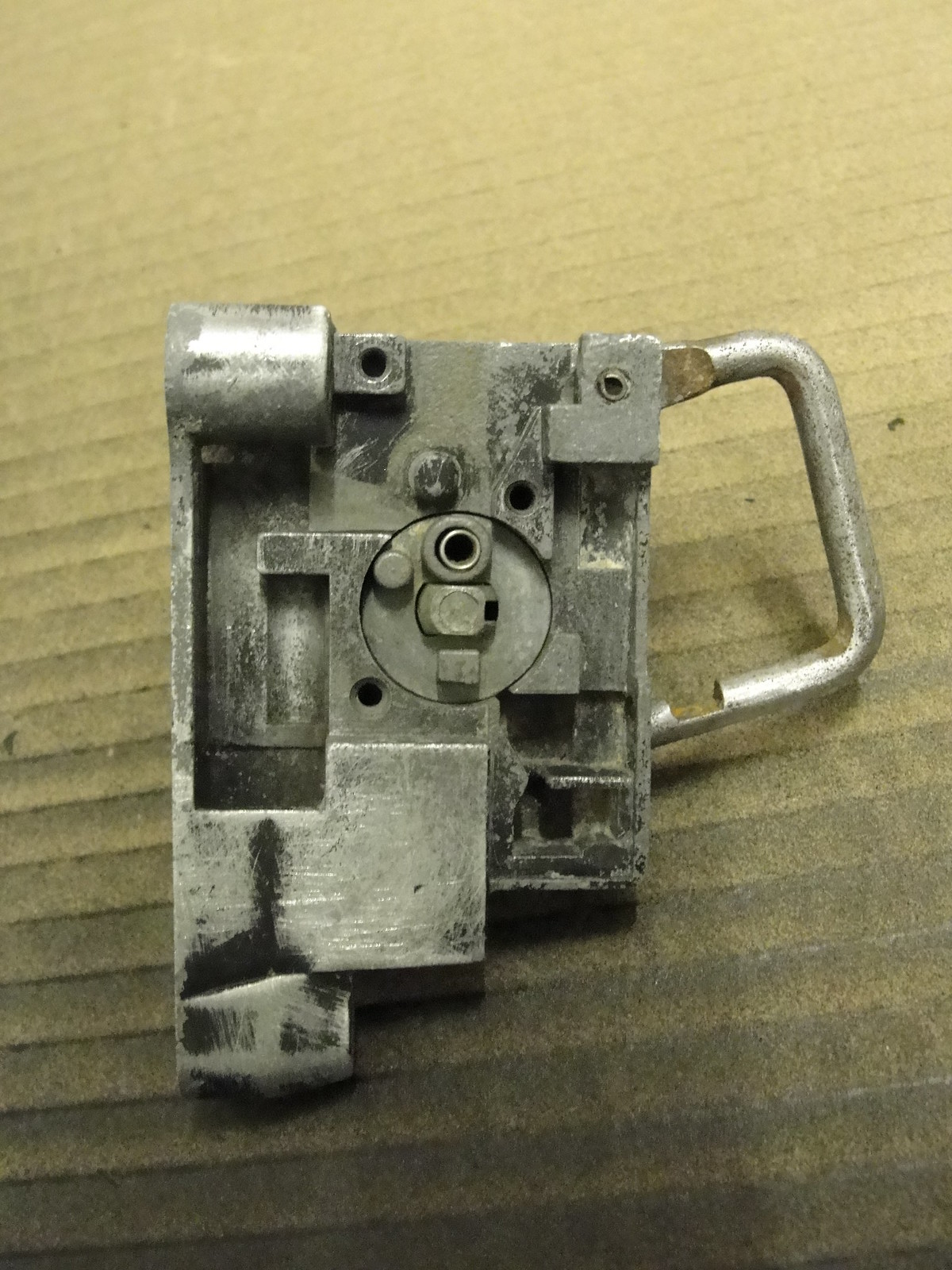

More fiddly bits today. I spent nearly 2 hours replacing the regulator 1/4" spades (soldering and crimping). I'm pleased with the result. I read about checking float height with interest. Seems one method is the clear tube method, as using the 21mm measurement does not actually take into account when the valve shuts. I have read some people use the overflow pipe ? The copper overflow tube in the float bowl is surely way too high to use this method  Anyway I figured the best way was to take fuel from the drain plug. Trouble is I needed to get back on the lathe.  I'll stick some petrol in tomorrow. Should it be level with the gasket? I also started on my next focus. Can you guess what they are going to be used for

|

|

|

|

Post by kevsypvs on Aug 24, 2013 22:13:39 GMT 1

sidestand?

|

|

|

|

Post by jon on Aug 25, 2013 18:20:54 GMT 1

kevsypvs it's not a sidestand. Guess again ?  If I get time tomorrow I will reveal a bit more. I realised today what people are going on about when they say they check the float height with a clear tube using the overflow. I am putting 31K carbs on my LC, and was only familiar with LC carbs before. For an LC you need to remove the drain bolt, and attach a clear pipe to the hole with an adapter (such as the smaller M5 adapters I made). However the 31K (and maybe all YPVS - someone will know?) float bowl is different. The drain bolt has a taper which seals a hole inside. I imagine you could just attach a hose to the brass nipple, and unscrew the drain bolt a turn or two. Anyway checked my float height today. First off I attached a pipe to the petrol infeed, and blew through it gentle whilst turning the carb. When the valve shut I checked the height with a ruler for the 21mm needed from gasket face to float. I then set the carbs at the angle they are when fitted to the bike, and filled them with petrol. Both were equal - and just below the gasket - job done.  I'd fitted new connectors to the regulator as the red one had completely corroded. Masked up the wires and sticker, and gave it a quick bead blast.  |

|

|

|

Post by jon on Aug 26, 2013 19:16:20 GMT 1

Made more progress on my mystery conrods, and made some bushes for them.  kevsypvs (or others), any guesses what they are going to be used for? |

|

|

|

Post by 2strokesmoke on Aug 26, 2013 19:44:59 GMT 1

Made more progress on my mystery conrods, and made some bushes for them.  kevsypvs (or others), any guesses what they are going to be used for? I,d have a guess at rear linkage dog bones??  but I,m no expert..lol Fantastic build btw loving it so far. |

|

|

|

Post by jon on Aug 26, 2013 19:57:24 GMT 1

Good guess 2strokesmoke (I thought the same when I asked the question).

More revealed tomorrow.

|

|

|

|

Post by flames on Aug 26, 2013 20:57:09 GMT 1

gear and brake lever?

|

|

|

|

Post by bare on Aug 27, 2013 17:43:46 GMT 1

DID 520 vt2 'enduro' racing chain is a specialised x ring type.

BUT it's pretty well exactly the same width and weight of a basic non o ring chain.

Massively strong as well as light.. a v good combo. Surprisingly reasonably priced, as small bonus.

|

|