|

|

Post by Tobyjugs on Oct 8, 2014 11:43:29 GMT 1

Hello chaps, been trying to adjust and check for correct running of a newly built ypvs engine with pinned valves. The engine was re-sleeved and larger pistons are used.

The problem i have is the bike runs very well until it comes into the power band (7500 rpm approx) At 8000 rpm the clutch begins to slip and it missfires very bad and begins to clear at 9000 rpm.

The setup is as follows;

Using 4L001 carbs

Air jet 27.5 screw 1.5 turns out

5K1 needle in middle position with P2 345 needle jets

Main jets 300

float height set to 21mm from carb gasket (I will check this again and may be make it 19.5mm to allow for thickness of gasket)

No Balance pipe between carbs

Timing not checked

Foam pod air filters

JL expansion chambers

Premix 30-1

I did a plug chop at 6000 rpm and the pugs were a light tan colour so i decided to lift the needles one notch to richen up the mixture but this only made it run worse at low rpm so put the needles back to standard.

I have now put three heavy springs into the clutch to help cure the slipping clutch. the weather is now very bad so i thought now would be a good time to ask for help.

I read on hear some where that if you re-sleeve the barrel you ruin the transfer ports. I hope this is not the cause of the miss-fire

When the weather clears i will do another chop at 9000 rpm if the clutch holds together. I the mean time any suggestions are gladly received. (normal ones, that is)

|

|

|

|

Post by muddyfox on Oct 8, 2014 17:25:19 GMT 1

could be lean on the premix, paradoxically if you add more oil you run leaner, i would rejet using 40-1( 88 ktm 500 50-1 loves this ratio as long as you jet it correctly, 100-1 on the new strokers ie snowmobiles and they run flat out all the time, i used to run 32-1 on my 500 before rebuild and it was sluggish, now it wants to kill me)

300 sounds way to big, hence the hesitation just as your coming on the pipe

the balance pipe, is properly sealed as a leak may give you a false reading and you may chase your tail, check for a leak!

you could mark the throttle in segments and this may help finding where it starts to miss, as in coming off pilot onto mains

saying this, your engine might be tight? give it some time and see what its like

cant help you with needle choices, im still learning the bike, my first rd to date, had plenty of other smokers,rg's cr's, vj21-22, rs's, gt's, 500mx's, kr1's, tm's, gasgas's

i dry seat my rings and have always had mega comp on my engines, always lube everthing else, kick her over around 50 times, then go back your the ratio you have always used

good luck

|

|

|

|

Post by greasemeup on Oct 9, 2014 2:10:59 GMT 1

could be lean on the premix, paradoxically if you add more oil you run leaner, i would rejet using 40-1( 88 ktm 500 50-1 loves this ratio as long as you jet it correctly, 100-1 on the new strokers ie snowmobiles and they run flat out all the time, i used to run 32-1 on my 500 before rebuild and it was sluggish, now it wants to kill me) 300 sounds way to big, hence the hesitation just as your coming on the pipe the balance pipe, is properly sealed as a leak may give you a false reading and you may chase your tail, check for a leak! you could mark the throttle in segments and this may help finding where it starts to miss, as in coming off pilot onto mains saying this, your engine might be tight? give it some time and see what its like cant help you with needle choices, im still learning the bike, my first rd to date, had plenty of other smokers,rg's cr's, vj21-22, rs's, gt's, 500mx's, kr1's, tm's, gasgas's i dry seat my rings and have always had mega comp on my engines, always lube everthing else, kick her over around 50 times, then go back your the ratio you have always used good luck Could you explain "Dry Seat my Rings" please? |

|

|

|

Post by Tobyjugs on Oct 9, 2014 8:04:21 GMT 1

I am not exactly sure what is meant by dry bedding the rings, but at a guess i would say run them in with less oil.

Stopped raining last night, so went out for another ride. but before i went out i checked that there was enough fuel flowing to the carbs, and replaced the plugs in the rubbers just before the reeds with the standard balance pipe. This has made an improvement, splutters much less but now more at 9000 rpm.

Today i will do a plug chop as it seems to be good weather.

|

|

|

|

Post by muddyfox on Oct 9, 2014 10:55:51 GMT 1

lol sure dry seat: leaving the rings dry, problem is honing now days is so fine that it doesn't take much to seat rings, in the old days, showing my age now

honing was very rough hence having to take it easy when running in,

so i de-burr the barrel, lube bearings and wrist pin, lube case bearings, complete build, with ignition off kick it over 50 times, start engine, do a heat cycle, allow to cool properly, another heat cycle, re torque head and rip!

hope this explains dry seat

|

|

|

|

Post by Tobyjugs on Oct 9, 2014 18:02:00 GMT 1

Honing liners for engines is specialist work get it wrong and you could have huge oil consumption or even worse some kind of siezure.

Any way back to my little problem, did plug chop and one was slightly light in colour and the other plug was nice tan colour, Strangely the the miss-fire was a bit intermitant today. First three gears nothing then the following gears problem

but it is a lot less with the balance pipe in place. I will check to see if it is sucking air in any where. Anyone got any other ideas?

|

|

|

|

Post by Tobyjugs on Oct 14, 2014 10:19:02 GMT 1

Hi Chaps back again, Checked for air leakage and was in two minds over the result so i pulled the left barrel and found this.  I have repaired it with some Wencom More bad news i saw that the piston had slightly siezed to the liner. (did not even notice or feel it when driving) I could not see any damage to the ring and used some special chemicals to locate the aluminium stuck to the barrel and carefully removed it. Another surprise was the form of the piston.  I was told that it had motor cross pistons, and i said oh alright then, because i did not know there was a difference, (not complaining) It is now back together and running much better with a slight hiccup at 8000rppm (so not cured) now running on 330 mains. It feels as flat as a pancake to ride. Next step will be the dyno to see what is really happening. this bike has a weak spark i can hear it but only just see it, so i will also get some coils from Norbo , and try some reed spacers. I am still in the dark so all input gratefully recieved. |

|

|

|

Post by muttsnuts on Oct 14, 2014 10:42:50 GMT 1

um, never seen those pistons fitted to a YPVS engine, might be worth checking what they are from and if they are suitable, they look very different to a normal YPVS piston, I suspect this will be changing the port timing/characteristics of the engine quite significantly, this could be your problem.

Is the reline/bigger sleeve you have a common one or something a bit different, just wondering what the pistons are off

Somebody on here might know, but I've not seen ones like that before fitted

|

|

|

|

Post by steeley on Oct 14, 2014 10:49:53 GMT 1

hmmm single ring piston and no windows in the rear of the skirt.also where the ring peg is I think there may be a danger of it catching in the boost port.been a while since I have had a cylinder head off.when you say the cylinders have been resleeved what size are the pistons now.also did you check the timing.

|

|

|

|

Post by nikfubar on Oct 14, 2014 10:50:15 GMT 1

I'm no expert by any means but the barrels & cases have been tuned, to what degree who knows  or even if it was done by someone who knows what they are doing. Those pistons have the windows in the wrong place so there going to work well, not  |

|

|

|

Post by Tobyjugs on Oct 14, 2014 12:06:17 GMT 1

Just a short note about the history of the engine, I blew up my original engine around twenty years ago, I was working in Holland and my colleague Hans Blauw asked if he could have a look at it. Six weeks later he gave it back to me fully rebuilt. At that time he was racing a 500cc side car in the European and Dutch championships against the likes of Egbert Stroijer. He never wanted money for it he just thought it would be fun. I did not know the spec until i got i checked in England at the beginning of this year, the tuner told me 392 cc standard ypvs tune, and after i asked the golden question is it ok the reply was "intereting tuning just run it and see what happens"

In the barrel there are two inlet holes and the pin for the ring runs on the liner between the holes, It is always in contact with the liner. That was one of the first things i checked.

I have now made a date for a dyno run on Saturday and have explained what i know about the engine. I can't wait, i find it very interesting!

|

|

|

|

Post by steeley on Oct 14, 2014 13:02:21 GMT 1

interesting indeed,good luck with the dyno tell us how you get on.

|

|

|

|

Post by Tobyjugs on Oct 14, 2014 13:10:01 GMT 1

If push comes to shove i might just drill a couple of holes in the back of the skirt.

|

|

|

|

Post by muttsnuts on Oct 14, 2014 14:17:59 GMT 1

would be interesting to see that piston sat next to an original/normal YPVS one, the bore size is 68mm, so would be interesting to know what the piston is off, at 392cc its sounding a bit of a one off mind, unusual size, suppose you won't know what the sleeves used are either ?

|

|

|

|

Post by Tobyjugs on Oct 14, 2014 15:11:06 GMT 1

When i lifted the head i noticed that the outside of the liner has penetrated the holes for the cylinder head studs by a couple of mm. One of the head studs would not tighten up correct so off with the head and found the thread goosed. Luckily i also have the correct helicoil set handy. A third of the hole is steel liner and the rest aluminium, so i had to make up a steel guide which i bolted to the barrel to guide the drill straight and true ha ha. It sounds long winded but it did not take to long as i have accumulated lots of stuff over the years. Most people call it junk but every now and again it turns out to be gold. When i bought the red and white lc i was proudly showing it off to friends and it would not start, it then mis fired and blew the baffle out. The end piece landed in the small canal. luckily half an hour later it was kind of repaired, using part of an old suspension bush from a land rover  |

|

|

|

Post by steeley on Oct 15, 2014 5:29:49 GMT 1

68mm bore ,its starting to sound like banshee bigbore stuff.the pistons are not banshee though.its turning into a good thread here looking forward to the dyno run now.check out TDR web site he sells a lot of banshee stuff.oh that was a quick fix for the exhaust end can lol.

|

|

|

|

Post by Tobyjugs on Oct 15, 2014 17:00:07 GMT 1

Did the bike ever run with this set up ? No this is the first time, i Have done about 120 miles it runs and starts fine. It has slight splutter at 8000 rpm and is a bit flat, You can compare it to riding an old GS550 |

|

|

|

Post by muttsnuts on Oct 15, 2014 17:05:40 GMT 1

Did the bike ever run with this set up ? You can compare it to riding an old GS550 I'd rather not if you don't mind !!   |

|

|

|

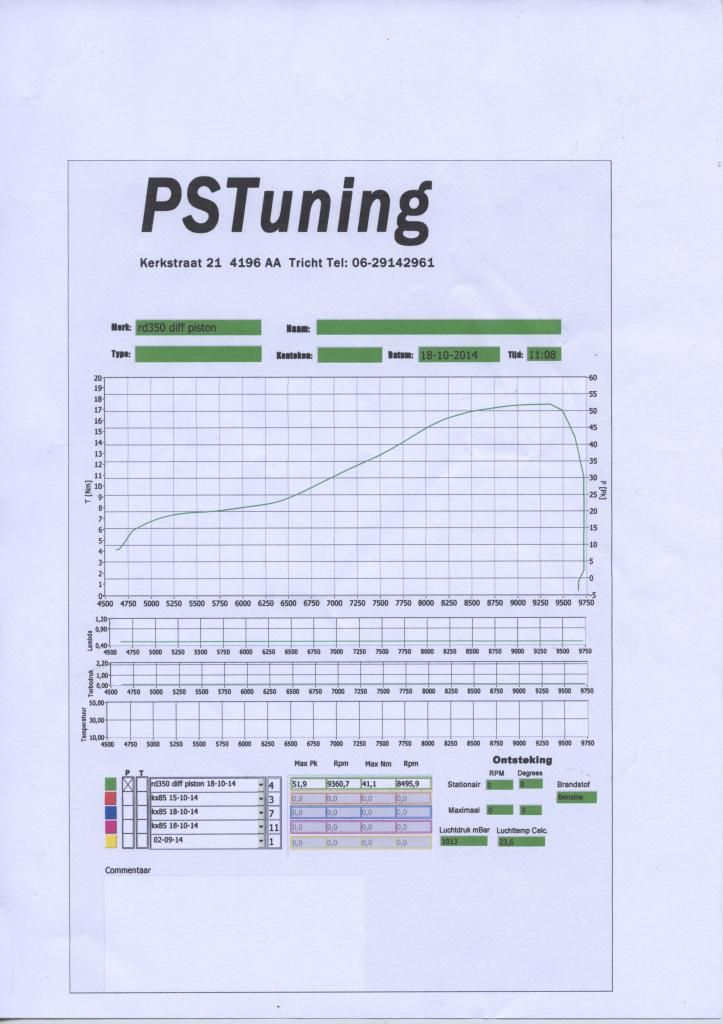

Post by Tobyjugs on Oct 18, 2014 14:16:36 GMT 1

Right chaps the results are 50 and a bit horse power.  If You give it full throttle the stutter is not apparent. It only happens on half throttle or so, i guess that make's me a big girls blouse then.  I have shown Pieter some pictures of the piston and barrels and he told me i need to have some ports in the pistons. I also told him it was a lot worse without the balance pipe and he explained that the balance pipe helps the breathing if the ports are not in the pistons. He also said he could here a strange noise at high rpm and measured the squish and found it to be about 0.7mm and told me about 1mm is good for a road bike. The bike was also still too weak but we did not bother to do anything about this as i will first take the top end off and see what i can find or make to try to solve the piston problem. Are the any options in thickness of base gaskets to buy or do i have to make my own? So who thinks i should try to find some new pistons and who thinks (like me) first have a play with the pistons i now have? Right where's me file?  |

|

|

|

Post by steeley on Oct 19, 2014 5:22:58 GMT 1

I think you will be better off making your own base gaskets its going to be cheaper plus its relaxing .I think you have already made your mind up about the pistons you have.you could do with an old ypvs piston to compare with the ones you have got in the engine I will have a look in my shed later pm me your address I will send one if you are stuck.

|

|

|

|

Post by Tobyjugs on Oct 19, 2014 8:59:49 GMT 1

Hi Steely, thank you very much for your kind offer. I do have some spare pistons to copy.

You are right i have made my mind up. I am going to modify what i have got and if it works get some proper pistons later. I only wonder how much will i weaken them by doing this?

I do not have much experiance with this type of engine so i love to have as much feedback as possible from forum members, Positive and negative i do not mind.

So first thing on the list today is to measure the squish on both units and remove pistons to compare to original. I will then add a few photo's to this thread for everyone to see.

The base gasket is the thing thats got me bothered, finding the right thickness, and what material to use ie, metalic type or paper type, i think i would prefer the metalic type with a smidge of sealant.

Right where's me spanner,

|

|

|

|

Post by tsa on Oct 19, 2014 9:02:56 GMT 1

That piston with no windows will have cost you bhp. How many is anyones guess but Id say no more than 4-5bhp at the most. 50bhp with all those mods isnt good really Id have expected nearer low 60's bhp to be honest. A good std YPVS will put out 45-48bhp all day long. Looks like you have bigger issues there unless the dyno reads very low of course.

|

|

|

|

Post by Tobyjugs on Oct 19, 2014 11:40:29 GMT 1

Just come out of garage to find my camera. What i have found is that the pistons are not phased, or timed correct assuming that they should be 180 degree's apart. Is this theory correct? When one piston is at TDC the other piston still has to travel 0.16mm before it reaches BDC I double checked this by putting both pistons at TDC and marking the fly wheel there is a discrepancy of 11 mm using a tape measure around the fly wheel  Right where's me camera |

|

|

|

Post by steeley on Oct 19, 2014 12:40:34 GMT 1

hi ,yes they should be 180 apart.this could be from the original blow up.it looks like an engine strip and get the crank sorted out .get that camera clicking

|

|

|

|

Post by nikfubar on Oct 19, 2014 13:49:35 GMT 1

Yup your cranks fubared, had this happen to one of mine, the weld broke & moved out a few degrees, it ran ok on the L/H cylinder but misfired badly on the right, I'm surprised you got the results you did with a twisted crank.  |

|

|

|

Post by Tobyjugs on Oct 19, 2014 16:35:52 GMT 1

Hello chaps as promised Picture's Here is a picture of the crankshaft deflection it was more but i touched the front clock by accident it is 0.16mm difference. Does anyone know what the original tolerance should be?  This is what mutts asked for so here are some pictures of the piston against an old standard piston.    This is the state of tune for you to see. The only difference i see is there are two small holes angled upwards in my liners, instead of one large hole in the standard liner.   All i ever wanted was plug and play. Well at least i get to learn something about these engines. The only thing i do not have is a fly wheel puller, once i get this i will be asking a lot of questions about tolerances. I think i am going to go for a ride on the red/white lc to give myself a bit of fun, fingers crossed i do not blow it up until this engine is fixed  |

|

|

|

Post by tsa on Oct 19, 2014 16:56:38 GMT 1

0.16 mm is 5.59* out question is it advanced or retarded. Retarded wont do much but to much advance can be catastrophic. The liner is very thick at the PV side and this will inhibit some of the good the PV does. It really needs to be within 1mm if the piston to be working optimally.

|

|

|

|

Post by midlifecrisisrd on Oct 19, 2014 17:00:26 GMT 1

I am by no means an expert but that barrel looks butchered.

The 2 inlet windows with no alloy bridging left in the barrel surely won't help flow.

Steve

|

|

|

|

Post by raven13 on Oct 19, 2014 17:10:29 GMT 1

its a blaster piston I think. ive got the same one here

|

|

|

|

Post by davecroucher57v on Oct 19, 2014 17:23:06 GMT 1

yz 250 pistons 68mm std size is the crank std try 420 mains

|

|