|

|

Post by dusty350 on Jun 17, 2019 7:05:11 GMT 1

Good job on those mate  They look "factory". I love all the little details like that. People would miss them if they didn't know about them  Dusty  |

|

|

|

Post by Tobyjugs on Jun 17, 2019 9:36:45 GMT 1

Good job on those mate  They look "factory". I love all the little details like that. People would miss them if they didn't know about them  Dusty  Thanks Dusty, i did try a few different ideas and materials before this was made. The man at Allens advised me just to thread the end and remove the carb and unscrew it from the cap. |

|

|

|

Post by Tobyjugs on Jun 17, 2019 10:01:16 GMT 1

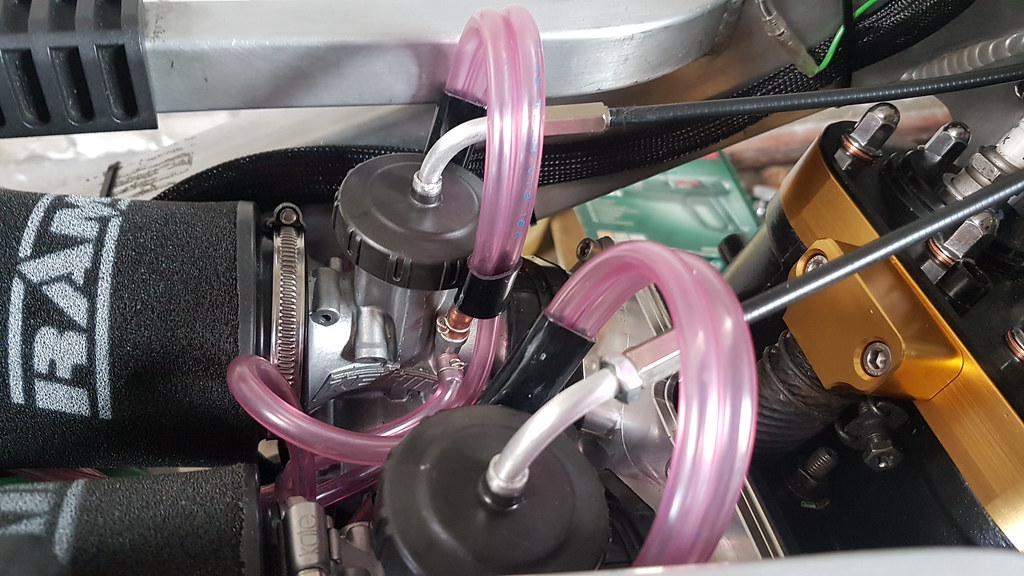

I also changed the Aluminium cooling water pipe, for a complete silicone pipe. I do like the look of the ally pipe but the silicone set up was 60 grams lighter.   |

|

|

|

Post by donkeychomp on Jun 17, 2019 22:38:59 GMT 1

Very trick. It's the little things like this that combine to make something really special.

Alex

|

|

|

|

Post by veg on Jun 17, 2019 23:07:43 GMT 1

Looks good tony, really coming on well. Be interested to see what it weighs I need to get weighed.

|

|

|

|

Post by Tobyjugs on Jun 17, 2019 23:12:54 GMT 1

Looks good tony, really coming on well. Be interested to see what it weighs I need to get weighed. Hi veg it's got to be around 100 to 105 kg |

|

|

|

Post by veg on Jun 17, 2019 23:15:53 GMT 1

That is going to be a cracking power to weight ratio.

|

|

|

|

Post by Tobyjugs on Jun 17, 2019 23:29:00 GMT 1

Still got some heavy bits to add, full fairing, chain etc. I think it's going to be around the 115 to 120kg dry

|

|

|

|

Post by Tobyjugs on Aug 18, 2019 12:51:49 GMT 1

At last I've been able to do some work on this bike. I fitted the throttle tops which i made just before i left home for work. This did not go as planned because the throttle cable nipple was too big for the teflon pipe. I had to fit the teflon pipe to the cable assembly and then push the teflon into the new bend along with the nipple.  I then mocked up a bracket to hold the tacho and Zeel in place. With this in place i can start making the wiring loom. The plan is to run get the wheels turning under their own power half way through September. Once that has happened it will only be a matter of fitting the faring a proper clock bracket and any mods to help air flow through the bike in the correct places.   With the Zeel in this position the interface port is in a difficult place for connection. I will probably make an extension from the Zeel up to the small dashboard once its made. In the picture below the clock is beginning to look small !!!  I only have to find a good place for he coils. Below are two possible locations. 1) Under the chassis rail. Access might be a bit awkward. Compact and out the way. 2) Make a small removable carbon fibre tray and mount them behind the head stock. Takes up space. Easy to access.   Any opinions where to mount the coils will be gratefully received as long as they are not rude  |

|

|

|

Post by muttsnuts on Aug 18, 2019 15:05:57 GMT 1

fasten a coil on either frame rail inside the frame above the cylinder head (I do this on my hybrids), just a couple of rivet nuts does the trick for each coil, and means they are firmly mounted, earthed already and dead easy to access, I can show you on one of my bikes when you pop across if you want

|

|

|

|

Post by 4l04ever on Aug 18, 2019 15:06:18 GMT 1

I would fit them up behind the head stock, so leaving more access to your engine from the outside. Or even fit one on the inside of each frame spare.

|

|

|

|

Post by Tobyjugs on Aug 18, 2019 15:28:08 GMT 1

fasten a coil on either frame rail inside the frame above the cylinder head (I do this on my hybrids), just a couple of rivet nuts does the trick for each coil, and means they are firmly mounted, earthed already and dead easy to access, I can show you on one of my bikes when you pop across if you want The chassis rail you have suggested was my first thought, then i dismissed it thinking that the left hand coil might might cause disruptive interference to the loom that will run along next to it. Two coils on the right hand rail could be too much. If everything goes well yes you can show me yours  |

|

|

|

Post by Tobyjugs on Aug 18, 2019 16:03:32 GMT 1

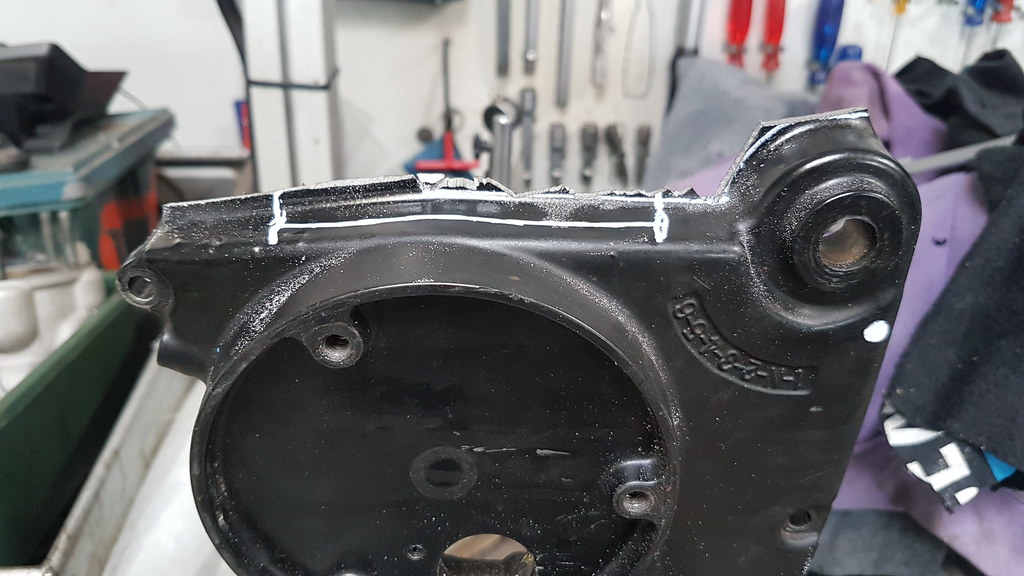

Ive just finished, solved the next piece of the puzzle  After a bit of measuring i decided to cut up a chain damaged 4LO chain cover to fit on the engine. It turned out better than i thought.  The sprocket is still hitting the fold in the casing so this was roughly marked out and set about with the grinder, now it fits.  The two white dots are where i will do some alterations. Where the bottom dot is, i will weld in a boss so i can use a bolt to give more support for the gear change. The top small white circle is where i will weld a support for a small sealed bearing for the output shaft. The position is really good leaving me a few options on how to finish it off. I might even shorten the generator cover as well. The idea is to try and cut a piece out mid section and then see if i can bolt the top back on. i can use it as a sort of inspection cover.  |

|

|

|

Post by 2banger on Aug 21, 2019 11:18:10 GMT 1

|

|

|

|

Post by Tobyjugs on Aug 21, 2019 18:02:15 GMT 1

Thanks Mr 2banger. I made some calculations and they came out at 400% more force with an average 443 engine spec. Not tuned. I'm not sure how accurate my sums are but I've now found out one of my work colleagues has a special program for this sort of thing. He is part of a team that does tractor pulling and the name of the tractor is The Judge. I will ask him to work it out properly. |

|

|

|

Post by 2banger on Aug 22, 2019 14:51:11 GMT 1

68mm Athena cylinders ?

|

|

|

|

Post by Tobyjugs on Aug 23, 2019 22:52:57 GMT 1

I have set of cheetah cubs a a set of driveline cylinders. At present the driveline cylinders are fitted. These are not tuned or cleaned up. First I want to see what's happening before the adjustments are made. |

|

|

|

Post by Yogi on Aug 24, 2019 17:00:15 GMT 1

Coming along nicely now mate,gonna be a proper beast when it’s finished 👹

Matt 🐻

|

|

|

|

Post by Tobyjugs on Aug 25, 2019 0:16:26 GMT 1

Cheers Yogi just got to find the balls to use such an engine 🤣😂🤣

|

|

|

|

Post by Tobyjugs on Sept 21, 2019 7:03:12 GMT 1

I'm going to try to start the Bakker bike up today

|

|

|

|

Post by dusty350 on Sept 21, 2019 7:15:11 GMT 1

Good luck  Don't forget the vid  Dusty  |

|

|

|

Post by Tobyjugs on Sept 21, 2019 15:51:30 GMT 1

Good luck  Don't forget the vid  Dusty  A little teaser for you

Click on the picture |

|

|

|

Post by Tobyjugs on Sept 21, 2019 20:15:07 GMT 1

So today was the day i started the engine. I don't know who was the most excited me or Piet the tuner i use. Here he is saying hello to another forum member who wished me luck. He's just tying the bike down on the dyno

First thing was to set the fly wheel in the correct position for the pickups. Whilst this was happening the new ally dampers were fitted. The fly wheel was tightened and then using the rolling road we could check for a spark. The fly wheel side had no spark. After checking the pickup signal it was noticed that i had crimped the connector to the plastic and not the copper. Once that was fixed it was all systems go. It started very easy and sounded nice but it is LOUD even with the long dampers. I still can't make my mid up about the silencers, i need to find some carbon/kevlar tubing and make a set to see which i like best. A few checks were made and the coolant had to be refilled. In the initial start ups its obvious to hear it was running a bit lean. Kees and i fitted the carbs with bigger jets and you could hear it sounded better and didn't want to react so nervous if you touched the throttle. Click on the picture below to see the vid

I don't think it actually ran for more than 15 minutes, mostly up and down on idle and it managed to easily drink a litre of fuel, and i thought i was used to thirsty two strokes !!! You might have notice the coloured marks on the cylinder head and spark plug caps. This is to stop any confusion because each plug has its own pick up if you put the cap on the wrong plug it will fire at the bottom of the stroke. One thing i noticed was how quick it warmed up which means my fears about the rad being too small are probably true. The bike will stay at Piet's place and when i get some time i will fine tune it and get the outer sprocket bearing support done. |

|

|

|

Post by Yogi on Sept 21, 2019 20:35:36 GMT 1

That sounds a mean old beast👹

Is that you hiding in the corner looking scared of it😬

Nice to here it running 👍

Matt 🧸

|

|

|

|

Post by Tobyjugs on Sept 21, 2019 20:52:40 GMT 1

That sounds a mean old beast👹 Is that you hiding in the corner looking scared of it😬 Nice to here it running 👍 Matt 🧸 Ha Ha i wish i was that build again, that's Kees in the corner. Definatley nice to see some colour coming into the header pipes |

|

|

|

Post by Yogi on Sept 21, 2019 20:56:16 GMT 1

I do love the first start up but it creates as many questions as it answers 🤔

|

|

|

|

Post by Tobyjugs on Sept 21, 2019 21:03:40 GMT 1

I do love the first start up but it creates as many questions as it answers 🤔 So far so good and I'm very happy with the gearbox as Piet said it changes gear nicely and first was easy to find. It's that mixture of YPVS and Banshee bits. No special mods made to selector star but maybe the shaft arms are all a bit longer. |

|

|

|

Post by donkeychomp on Sept 21, 2019 21:57:26 GMT 1

That sounds incredible. Brilliant job!

Alex

|

|

|

|

Post by oldbritguy on Sept 21, 2019 22:23:44 GMT 1

Sweet!

You have got to be pleased with that Tony. Sounds amazing.

|

|

|

|

Post by Tobyjugs on Sept 22, 2019 5:30:21 GMT 1

Sweet! You have got to be pleased with that Tony. Sounds amazing. Very pleased, the noise is a bit distorted using the telephone |

|