|

|

Post by Tobyjugs on Aug 8, 2021 18:44:54 GMT 1

A proper nice looking machine 🥰 Only criticism is the seat looks uncomfortable 😅😅😅 Good timing Yogi Last Sunday i rattle canned the seat unit and today i polished it. I also made a template for the seat foam, cut the seat foam and sanded it down for what seems ages and stuck it in place. Hmm the juries out on the foam, it's very grippy! Not so good for lazy me when shifting from one side of the bike to the other.    |

|

|

|

Post by peddrotzr on Aug 8, 2021 19:03:53 GMT 1

Looks Fabulous  |

|

|

|

Post by midlifecrisisrd on Aug 8, 2021 19:45:17 GMT 1

Mint 😎

For the TR I was thinking of foam over some 9mm ply then covered in vinyl

Screw it on from underneath

Steve

|

|

|

|

Post by dusty350 on Aug 8, 2021 21:16:37 GMT 1

Looking really lovely now Tony   |

|

|

|

Post by JonW on Aug 9, 2021 3:17:17 GMT 1

Looks Fabulous  +1! |

|

|

|

Post by oldbritguy on Aug 9, 2021 7:02:39 GMT 1

That is a thing of beauty Mr T. What a beautiful build!!!!! Certainly looks very nice and comfy as a sitting room ornament, and a fantastic conversation piece as well. Time for the track yet? John  |

|

|

|

Post by Tobyjugs on Aug 12, 2021 18:26:45 GMT 1

That is a thing of beauty Mr T. What a beautiful build!!!!! Certainly looks very nice and comfy as a sitting room ornament, and a fantastic conversation piece as well. Time for the track yet? John  I will have some time off soon and will be looking for some track time for shake down tests Just need to get some proper tyres and new disc pads I also weighed the bike and to my delight and surprise it came in at 104 kg. That was only with about 2 litres of fuel though. Pity I'm heavier than the bike  |

|

|

|

Post by Tobyjugs on Aug 12, 2021 18:29:11 GMT 1

Mint 😎 For the TR I was thinking of foam over some 9mm ply then covered in vinyl Screw it on from underneath Steve The next time i see a TR i will make some pictures and ask about seats for you Steve |

|

|

|

Post by jon on Aug 12, 2021 18:43:18 GMT 1

Mint 😎 For the TR I was thinking of foam over some 9mm ply then covered in vinyl Screw it on from underneath Steve Hi Steve, I would try a bread board myself. Waterproof, and possible able to heat and shape it. Sorry for the hijack Tobyjugs. Jon |

|

|

|

Post by Tobyjugs on Aug 12, 2021 18:47:35 GMT 1

Jon thats a good idea, i am going to use that for the seats in my Landy

|

|

|

|

Post by arrdy350 on Aug 12, 2021 20:21:24 GMT 1

Excellent build 👍

|

|

|

|

Post by Tobyjugs on Sept 1, 2021 11:01:46 GMT 1

Hello chaps back again. A couple of little things that still need to be done have now been addressed. To be honest i was planning on doing these after the first couple of runs in the real world on the track. I've had these for a while but have now fitted them.  There are two different pad types which i pondered over using. The Brembo SR and the RC type pads. I was going to go for the SR type which are more biased street/track day type pad. I thought this would suit me better as the bike is only 105 kg (dry) so not so much effort needed to stop it and i have only been on track days as a novice and usually somewhere around the end of the pack. Having said that i was advised to get the RC type. When i started waffling on about weight etc i was reminded about my weight, and the extra effort to needed to slow down  So the RC pads were fitted. I even got an instructional video sent to me about how to gain extra HP.  Click on the picture below.  Next on the list was to prepare the tank.  The the foam is called Explo-Safe and is used to help prevent any fire issues and keep the fuel from slopping around fuel tank. The foam has large holes in it so it leaves plenty of room for the fuel.  This was cut into chunks and stuffed into the fuel tank. Just like which oil to use there are basically two ideas about fitting it. Big pieces or small pieces, i went for big small pieces Ha Ha. The foam is very easy to cut up using a sharp bread knife, this also keeps any small bits to a minimum during the cutting process. The pieces were thoroughly cleaned and then placed into the tank. More foam can be fitted but i left this out, the part just under the fuel cap has a gap of about 7cm. This gap was left so i can see the fuel level. If it was completely filled i would not have any idea much fuel is in the tank unless i weighed it.  I have also had a small mechanical failure. More about that later. |

|

|

|

Post by Tobyjugs on Sept 1, 2021 20:32:52 GMT 1

At last, this turned up.   I'm looking forward to making some new gear change rods now. I never really like the one below. It reminds me of Tommy Cooper's magic wand.  |

|

|

|

Post by oldbritguy on Sept 1, 2021 21:12:27 GMT 1

Tommy Cooper Haha

showing your age there Mr T

That quickshifter looks nice. Has it joined the weight watchers queue as well?

|

|

|

|

Post by Tobyjugs on Sept 2, 2021 7:57:49 GMT 1

Tommy Cooper Haha showing your age there Mr T That quickshifter looks nice. Has it joined the weight watchers queue as well? Ha ha yes i have weighed it. It adds a massive 65 grams to the bike. I have thought of a way to win it back, without going on a diet. |

|

|

|

Post by marrcel on Sept 2, 2021 8:19:48 GMT 1

Helium inflated tires? 😜

|

|

|

|

Post by donkeychomp on Sept 2, 2021 21:20:09 GMT 1

I wonder why that idea never took off?

Sorry, sorry...

Alex

|

|

|

|

Post by steeley on Sept 4, 2021 8:12:56 GMT 1

Nice .

|

|

|

|

Post by Tobyjugs on Jan 29, 2022 21:21:11 GMT 1

Time to update this project a bit. Not sure where to begin so i think i will begin with last August /September. September i had a whole month off work so with that in mind i wanted to get the bike out on the track. I was still messing around with the clutch and the output of the engine seemed to be going up and down a bit. I made the clutch super strong and decided to test it on the back roads where i live. This was not a good idea and to be honest i was a little bit disappointed. The roads were too bumpy and the first 3 gears are too short leading straight to wheelies. So back to the dyno bank.  Can't quite recall this piece but due to a low tyre pressure or the weight difference between me and Pieter (the dyno owner) it was noticed the bike made more or less power. This lead to the conclusion the bike had been spinning the rear tyre up on the roller of the dyno bank. A lot of clutch work was done for the wrong reason. So with the bike now being tested with the wheel firmly in place on the dyno bank every thing was fine and the power was reading 97 PK without slip. Pieter suggested we do some runs to check the speed and gearing which i thought was agood idea. So whilst doing this the clutch siezed. Then that sinking feeling came to me as i knew it was my fault. I started out using a steel ball bearing then later swapped it to a ceramic ball bearing because of the thought of it seizing as i was upping the strength of the clutch. The last time i put the clutch together i dropped the ceramic ball on the floor and couldnt find it. Due to me wanting to sort it all before September i put the steel ball bearing back in.  If you click on the picture below you will see the video where the clutch siezed.  It turned out i couldn't pull the clutch actuation shaft out because it had mushroomed on the otherside of the shaft as well. I had to split the engine.

Pedrotzr came to my rescue and within a few days i had a thrust bearing and i got some more ceramic ball bearings. Just before Xmas i found the original ceramic bearing on the floor. When i first decided to build this project i asked Pieter from PS=Tuning to help me. He was very enthusiastic but he had one condltion. This was that we keep the engine power at around 85-90 PK he knew Kees would also be riding this bike and wanted to make sure that it wasn't too harsh. He said to me "i know you will be afraid of it and throttle off, but Kees won't". I totally agreed with him on that. After i repaired the siezed clutch mechanism the bike was back on the dyno and adjusted to 90 PK. In August i ordered some Bridgestone R11 tyres whiich didn't arrive until October. This was frustrating but all the circuit days were also fully booked and there was a waiting list for anyone who dropped out. This meant i still haven't been able to test the bike. When i went back to PS-Tuning to check the ignition timing etc after i had split the engine, the bike wouldn't start. Things between me and Pieter started to get irritable as Pieter started messing around with the leads etc and i was saying it wasnt necessary. I did warn him the timming could be slightly out due to there being no keyway to locate the flywheel to the crank. It turned out that the kill switch was playing up first not working and later intermittently I did set the timing bang on the nose from the last time. All tension for nothing. Just a short spat, not a problem for friends. I went on the hunt for a new kill switch. Kees for a joke bought me one of those handlebar GP switch cluster from Aliexpress for 4 euros including post. This give me an idea. The way my bike is wired up i have no battery and only a capacitor. Once the bike is bumpstarted the power is autamically fed to the tacho. I didnt like this much and was contemplating modifying the tacho bracket so i could fit an on/off switch and a menu button next to the tacho. No need with one of the clusters. I ended up with one of these.  I got in touch with CNC Racing to ask them about the switch specifications as all the models i had seen were for different types of Ducati's. They asked all the normal questions like which make/model and year bike is it. I've got used to this now and explained to them it is a one off project and sent them a picture of the bike and what i am trying to achieve. I had return e-mails usually within half an hour of my sent e-mails and they asked me what i wanted and built the switch to my spec. This took less than 20 days from my first e-mail to recieving the switch. The most surprising part was the bespoke switch was much cheaper than the advertised switches for Ducati's That's a big thumbs up for CNC Racing. Once i got the switch i changed my mind and wanted to mount it on the clutch side of the handle bar. To do this i had to make a clamp for the switch cluster. So a quick chat with a friend and off i was to his shed with some ally bar to make a clamp. This was made very easy by using a tiny work bench size milling machine. He made the basic form for me which i then shaped with some hand files.

Sometimes i just can't make my mind up. I've now fitted the switch cluster back to it's original position bolted to the brake lever.   So i took the lazy expensive option by using the CNC Racing buttons. It is however neat and tidy and IP68 rated. |

|

|

|

Post by steeley on Jan 30, 2022 7:16:05 GMT 1

Mint 😎 For the TR I was thinking of foam over some 9mm ply then covered in vinyl Screw it on from underneath Steve Hi ,for my Tzr 350 i cut a plastic seat base out of a 25ltr drum . Then cut some foam , i made some captive studs to go through the base to attach it to the single seat unit then stuck the foam on and covered the foam with a piece of old seat cover. |

|

|

|

Post by jon on Jan 30, 2022 10:28:35 GMT 1

Not such a stupid idea to inflate tyres with another gas other than air. Of course the above was a joke, and would offer negligible benefits for 2 or 3 days until the tyres went flat due to the tiny molecules of helium passing through the tyres or bead. However go the other way with nitrogen (which has a large molecule size) and you have a small improvement over air. Not quite sure how they evacuate the uncompressed air from the tyres first if at all. Anyone know? Jon |

|

|

|

Post by Tobyjugs on Jan 30, 2022 11:12:23 GMT 1

Not such a stupid idea to inflate tyres with another gas other than air. Of course the above was a joke, and would offer negligible benefits for 2 or 3 days until the tyres went flat due to the tiny molecules of helium passing through the tyres or bead. However go the other way with nitrogen (which has a large molecule size) and you have a small improvement over air. Not quite sure how they evacuate the uncompressed air from the tyres first if at all. Anyone know? Jon I just googled it and found this; |

|

|

|

Post by midlifecrisisrd on Jan 30, 2022 11:45:05 GMT 1

Remember when we used Kwik fit for our company cars years ago they used to offer nitrogen for a quid extra

Not sure if it's standard practice now or was just a fad

Biggest benefit was it was not affected so much by temperature change so less pressure difference between cold and thrashing

Steve

|

|

|

|

Post by oldbritguy on Jan 30, 2022 12:16:22 GMT 1

Some folk are just happy fitting blingy off the shelf parts to their bikes. Not this one  The kill switch you have fitted is a lovely little touch there  Great stuff Mr T John. |

|

|

|

Post by Tobyjugs on Jan 30, 2022 15:04:30 GMT 1

Some folk are just happy fitting blingy off the shelf parts to their bikes. Not this one  The kill switch you have fitted is a lovely little touch there  Great stuff Mr T John. It might be a bit out of period but it is much tidier than having switches next to the tacho. |

|

|

|

Post by Tobyjugs on Jan 31, 2022 10:03:17 GMT 1

Another small modification i made was to the left hand engine side casing. I wanted quick and easy access to the flywheel for visual inspections, so i decided to cut the top round part of the casing off. After a bit of checking i marked where i wanted to cut it.  I wasn't sure how this was going to turn out as the round part of the cover has a taper and i was thinking about reducing the height of the casing as well. Whist cutting through the side cover it went a bit wrong and it started to cut it wonky. I was very lucky not to ruin it and after straightening both pieces up i had reduced the height by roughly 3-4 mm. This reduction in height is not much but any lower and the end of the crankshaft would be touching the cover. Due to the taper of the round part of the side cover the end lid is slightly smaller in diameter than the rest of the side cover. You can see this in the picture below, when the two parts are painted black it will be harder to see.   |

|

|

|

Post by jon on Jan 31, 2022 10:40:14 GMT 1

That is without a doubt a really nice modification.

Can’t see it being of much use to me, but that doesn’t stop me wanting to copy it.

Why have I not seen this done before?

Jon

|

|

|

|

Post by Marcel on Jan 31, 2022 10:58:29 GMT 1

Nice project!!

|

|

|

|

Post by Tobyjugs on Feb 5, 2022 9:07:53 GMT 1

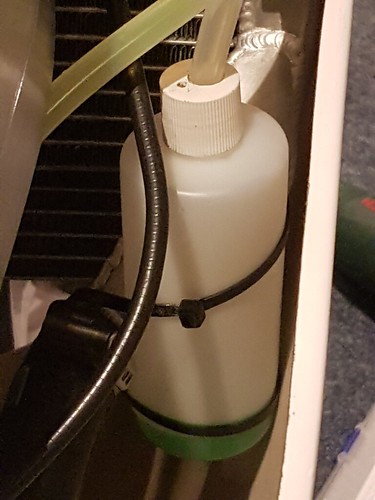

I still hadn't fitted an expansion tank as i keep imming and amming where i need to put it and also what i was going to use. In the end i decided to use a sample bottle that we use for collecting engine oil. This was a little bit big but it was ok. I decided to heat the back of the bottle up to make it flat so i could put it next to the radiator. I started to gently heat it up and it started to turn from white to clear. I stopped heating it but shortly after a big bubble appeared in the plastic and just burst. Bugger. With that plan dashed i statrted to think about a plan B. A couple of days later whilst tidying up i found a bottle of nail remover. The bottle was a better size although i thought the top was a bit small. Anyway i don't need nail varnish remover so a second attempt was made at deforming the bottle. This time very caustiously i managed to deform it. The bottle being smaller did help. With the lable removed i fitted it to the bike.   The only thing i have to do is stop the brake pedal from lifting too high. This is easy to fix with a stop but i just can't think of a solution which doesn't look like engineering from a "Victorian Bridge Engineer" I dont want to start drilling holes everywhere in the Bakker rearsets.  If anyone has any ideas please post them up. At the moment a spring is on the top of my ideas list.  |

|

|

|

Post by midlifecrisisrd on Feb 5, 2022 11:40:45 GMT 1

Could you not get a bit welded on the rear of the brake pedal in front of the pivot so it rests on the under edge of the hanger bracket?

Steve

|

|