|

|

Post by Tobyjugs on May 21, 2020 21:17:19 GMT 1

Today i have been doing a little bit of fettling. I removed a little bit of the front seat unit to help the fitting and removal of the tank that little bit easier.  I then washed and cleaned out the tank with WD40 to prepare it for fuel.  One of things which always annoyed me was all the pipe work from the carbs. Today i decided to tidy them up. Instead of tie wraps i used some heat shrink tube which worked pretty good.  I have also got the fairing stays made, fitted the RPM meter and started on the wiring.   Next on the list is the offset bearing carrier.  |

|

|

|

Post by oldbritguy on May 21, 2020 21:31:05 GMT 1

Nice one Tobyjugs. Neat little touch with the heat shrink too though I would probably have melted the hoses in the process.

Really love this build and nice to see it moving again.

John

|

|

|

|

Post by dusty350 on May 21, 2020 21:34:40 GMT 1

Nice work Tony  Little jobs, but they make a big difference  Dusty  |

|

|

|

Post by Tobyjugs on May 22, 2020 21:13:25 GMT 1

This bike uses a huge offset for the front sprocket. I decided i would use an extra bearing on the end of the shaft to help support the end of the output shaft. There is a design which looks nice to the eye and very functional made by Chariot. On further inspection this would not be any use to me without modifying it.  After a lot of thinking and staring at the problem i decided to modify my own engine casing, I have a few chain damaged cases so i thought what have i got to loose. So here it is.   The plate in the casing that the bearing holder is attached to is not so thick but it is supported by 3 webs on the inside of the casing. This is plan A and i will be testing it shortly to see if it's man enough and doesn't generate too much heat in the bearings. |

|

|

|

Post by Tobyjugs on May 23, 2020 18:24:00 GMT 1

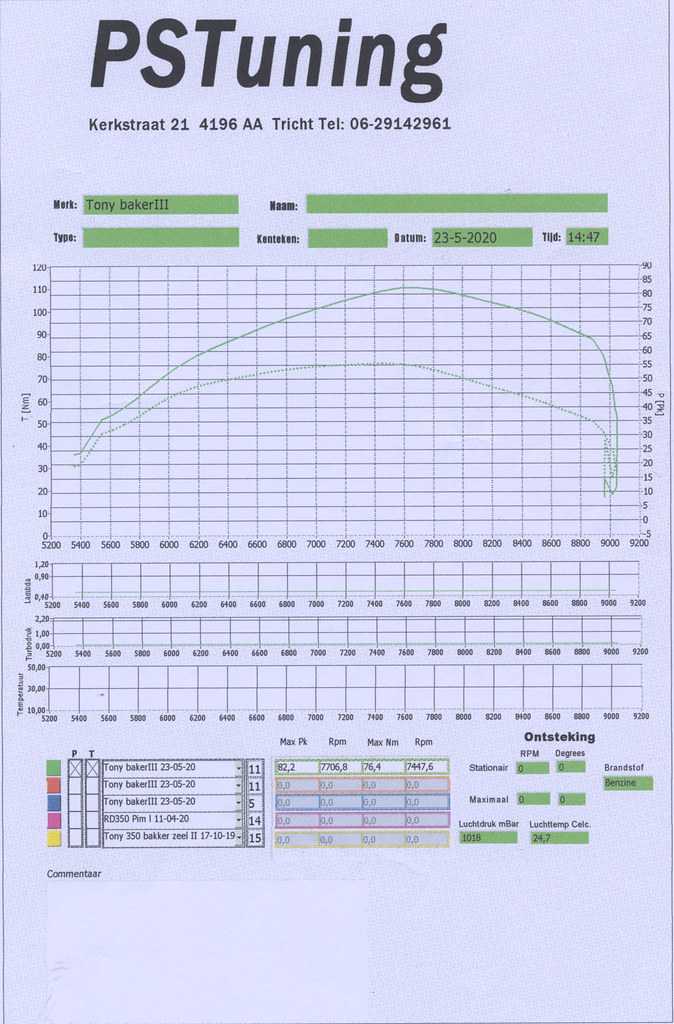

Today i have run the bike up on the dyno, with mixed feelings.  Bad Bits: Radiator is too small as i want to be running much cooler temperatures than this is capable of. The rad never overheated but it's not very efficient at spreading the coolant through the whole radiator. The power curve from the dyno read out is great for the LC caravan club but not for me. Its all over by 7800 rpm, 82 PK and 76nm. Good Bits The slightly heavier springs in that clutch kit from Barnnet are doing there job and the clutch is working fine. The new offset bearing holder has not destroyed itself, it's not making any funny noises and the temperature is normal. In fact it's hotter by the genny side than the sprocket side.  Testing the bike on a private long straight road showed how effective the long Banshee first gear is. This was also helped by using an 18 teeth front sprocket. The banshee first gear is something i would recommend if you don't go the bespoke gear train route. Even in 3rd gear you have to pay attention to the throttle if you want to keep the front end on the ground. There was a man who dropped by and it was a friend of Pieter the tuner. He really started looking the bike over and touching it while it was running. He said that it sounded nice and that it run very smoothly without too much vibration. Later i learned he was the mechanic from Ferry Brouwer. So that's a thumbs up. I asked him about the riders he met at the Allstars Event in Assen and he started showing me pictures of him with Christian Sarron and shooting guns with Kevin Schwantz on the family farm in America. I'm really looking forward to learning more about the dark art, and adjusting the engine specs to get a nice dyno graph that rises and drops off sharpish. I now have one which looks like a upside down smile. I did measure all the engine parameters when i built this engine and the cylinders are stock out the box. Now they will be cleaned up and adjusted. I'm not looking for big numbers on this engine. |

|

|

|

Post by veg on May 23, 2020 20:24:01 GMT 1

Tony

Re your fuel lines, I used some little alloy brackets for my fuel lines and my brake lines have a look in my build obviously heavier than heat shrink but they look great, if you can mount them somewhere.

Also I’ve just found myself reading your post in a slightly Dutch accent .

Lockdown getting to me I need out. 😁

|

|

|

|

Post by Tobyjugs on May 27, 2020 20:18:18 GMT 1

Below is the Dyno readout from last Saturday. It has received mixed reactions Some have said it is good and others have said it could be better. I'm in the it could be better camp. This dyno readout is good for the LC Caravan Club.  First the port timing was checked  The cylinders have now been removed for a slight clean up and a very small amount of port timing alteration. I really like the beam frame construction as it makes it very easy to work on the top end of the engine.  I'd love to hear some views over the graph above. Are you in the caravan club or not??? |

|

|

|

Post by oldbritguy on May 28, 2020 22:33:05 GMT 1

I am not in the LC caravan club but I am impressed with the dyno readings. 82pk @ 7.5k nice!!

That plus all the engineering, fabrication and weight saving on this lovely special means this will be one rapid machine

I am sure though you will tweek out a few more ponies

John

|

|

|

|

Post by veg on May 28, 2020 22:45:16 GMT 1

Tony i am firmly in the caravan club until i get my mutts pipes. What is most impressive though for me is the green lined oil tray that is about the coolest drip/oil tray i have seen for a while ten out of ten for bling my friend.

|

|

|

|

Post by Tobyjugs on May 28, 2020 23:38:39 GMT 1

Tony i am firmly in the caravan club until i get my mutts pipes. What is most impressive though for me is the green lined oil tray that is about the coolest drip/oil tray i have seen for a while ten out of ten for bling my friend. Don't you just luv green transmission oil  Very brave of you to stand up and be counted for the LC Caravan Club Tim. Cant wait to see mutts turn Mr Hyde back into Dr Jekyll |

|

|

|

Post by Tobyjugs on May 28, 2020 23:47:47 GMT 1

Managed to put the bike back together and do one dyno run before getting kicked out the workshop.

It looks like i might be excommunicated from the LC Caravan Club

|

|

|

|

Post by 4l04ever on May 29, 2020 0:05:28 GMT 1

Could you make your rad double or triple pass? To make it triple may be easiest, but would need to move the outlet lower on the right side.

I run double pass on mine with a modified Thundercat radiator.

|

|

|

|

Post by Tobyjugs on May 29, 2020 9:37:02 GMT 1

Could you make your rad double or triple pass? To make it triple may be easiest, but would need to move the outlet lower on the right side. I run double pass on mine with a modified Thundercat radiator. Hi Rob I will probably use a double pass radiator with a constant flow thermostat. |

|

|

|

Post by veg on May 29, 2020 13:28:07 GMT 1

My bloody eye sight is getting worse I genuinely thought you had a painted and lined drip tray now when I look I can see the green is reflected all the way to the rim. Jesus it’s getting worse, I must stop speaking without looking properly.

|

|

|

|

Post by Tobyjugs on May 29, 2020 15:28:26 GMT 1

My bloody eye sight is getting worse I genuinely thought you had a painted and lined drip tray now when I look I can see the green is reflected all the way to the rim. Jesus it’s getting worse, I must stop speaking without looking properly. Ha Ha its coolant in a stainless steel thingy. It does look nice now you mentioned it |

|

|

|

Post by Tobyjugs on May 29, 2020 15:33:51 GMT 1

I am not in the LC caravan club but I am impressed with the dyno readings. 82pk @ 7.5k nice!! That plus all the engineering, fabrication and weight saving on this lovely special means this will be one rapid machine I am sure though you will tweek out a few more ponies John Thanks for the nice compliment, it does seem tho, that when you get one part right it throws another part out.   |

|

|

|

Post by Yogi on May 31, 2020 18:40:05 GMT 1

Blood hell Tony that’s come along way and impressive power too 👍

The top end looks a pleasure to work on for a change

Nearly there now mate you must be pleased 😁

Atb Matt 🧸

|

|

|

|

Post by Tobyjugs on Jun 1, 2020 0:58:07 GMT 1

Blood hell Tony that’s come along way and impressive power too 👍 The top end looks a pleasure to work on for a change Nearly there now mate you must be pleased 😁 Atb Matt 🧸 Hi Matt, yes i'm chuffed to bits, but tweeking it for a little better engine performance is showing the rubbers in the engine block are a little too soft. So thats the next little project. |

|

|

|

Post by stusco on Jun 1, 2020 7:47:14 GMT 1

My bloody eye sight is getting worse I genuinely thought you had a painted and lined drip tray now when I look I can see the green is reflected all the way to the rim. Jesus it’s getting worse, I must stop speaking without looking properly. I looked at the time of your first post and thought someone’s been drinking 😀 |

|

|

|

Post by midlifecrisisrd on Jun 1, 2020 8:49:07 GMT 1

It must feel strange riding it with such a big peak so early but still making good power after

Would think you can get another 10 up out of that and higher up the range 👍

Steve

|

|

|

|

Post by Tobyjugs on Jun 1, 2020 9:09:12 GMT 1

It must feel strange riding it with such a big peak so early but still making good power after Would think you can get another 10 up out of that and higher up the range 👍 Steve It just felt like a big four stroke.  With a bit of a clean up of the cylinders it's making just under 90 but still needs to be set up. So i think it will hit 90 when finished with peak power around or just under 9000rpm. Ive been getting a bit of a ragging from two of the 250cc guys. I think this is a good sign.  I need to source a new rubber mount and then see how i can improve it for my situation. I have a 3 stage plan so far. (This could change) 1, Make some dished spacers to fit in the place of the rubber mounting washers. 2, Remove all the rubber bushes and fit aluminium to see if the frame mounting points are flexing 3, Try to make some sort of poly bush |

|

|

|

Post by midlifecrisisrd on Jun 1, 2020 11:19:57 GMT 1

Have you got 4 rubber washers fitted?

Steve

|

|

|

|

Post by Tobyjugs on Jun 1, 2020 18:51:35 GMT 1

Have you got 4 rubber washers fitted? Steve Yes I think this is no good. |

|

|

|

Post by Tobyjugs on Jun 4, 2020 21:56:04 GMT 1

I wont have much chance to adjust the carbs and ignition for a few weeks. This gives me time to put my thinking cap on and try to find solutions for the clutch and the engine movement in the frame. I have been given some good advice about the engine movement so i have lots of ideas bouncing around to try and find a good solution, but before i attack the engine mountings i will first try to improve the clutch. I have now made an eight plate clutch.  I have a couple of different baskets and they all differ slightly in length when using the 8 plate Hinson clutch hub. I'm not sure which make of basket is pictured in the photo above. Behind the clutch hub normally there is a 3mm ground washer. I have ground this washer down to 1.5 mm. This helps create the room needed for the extra steel and friction plate. Making the ring thinner allows the hub to drop deeper into the basket allowing the extra plates. I need to compensate for the thinner washer by adding another washer at the front of the hub under the nut. This washer has to be the same thickness of what was removed from the ground washer. I think i will make this out of aluminium or titanium. The top of the last friction sits 2 mm deeper than the top of the basket, in original condition this height difference is 3mm. A clutch cover from a YPVS will fit over the clutch without fouling. If the clutch does foul when it is operated i will probably machine the pressure plate in the offending area. The spring tension length between the two set ups are 22mm for the 8 plate version and 23 mm for the standard version. Below you can see the difference between a standard Yamaha hub and an 8 plate Hinson hub.  |

|

|

|

Post by veg on Jun 5, 2020 6:50:45 GMT 1

Calling mr jugs you have an appointment in the general chat area of the forum.

|

|

|

|

Post by marrcel on Jun 5, 2020 8:43:15 GMT 1

A good read for me Tony👍 thanks for sharing.

To keep your brain cells spinning, what about lock up and dry operated?

|

|

|

|

Post by Tobyjugs on Jun 6, 2020 9:02:24 GMT 1

A good read for me Tony👍 thanks for sharing. To keep your brain cells spinning, what about lock up and dry operated? Hi Marrcel I'm working on a dry clutch which is my final goal for this bike you can see a bit of it in the 8 plate clutch picture.  I have fitted a slingshot locking clutch to a 4LO engine and this works very well indeed. It is made for the YPVS engine not the 4LO but with a few mods and a YPVS clutch cover it will fit. |

|

|

|

Post by Tobyjugs on Jun 13, 2020 19:59:05 GMT 1

I think the stars and planets must have been aligned as i did not expect to do and dyno adjustments today. Sorry i don't have a nice printed graph for you, but here is the results of the last 3 visits to dyno bank for a small recap. Its just north of 90pk and 80nm torque. Its peak power is around 8,400 rpm.  I have actually been on the dyno bank 4 times, the first time my so called uprated clutch give up the ghost before it hit 7000 rpm. To be fair that was due to a spring breaking. One repaired clutch later the following three sessions were made. Pink The pink line is the end result of adjusting the timing and carbs to suit the out of the box cylinders. I also lowered the geometric compression ratio to 11.7:1 this might be still too high after a chat with Piet the tuner. Green The cylinders were cleaned up and only a small amount of tuning was done, this was to alter the shape of the Boysen exhaust ports which were originally two round holes which Piet didn't like. I managed to put the engine together before the end of the day so we made one dyno run. Red This is the carbs and ignition adjusted to suit the tidy up of the cylinders. At the beginning of the session he adjusted the resistance of the dyno bank because there was not enough heat build up in the exhausts to make them work properly. After adjusting everything he made a few runs changing through the gears. He had a big smile on his face and said he couldn't change gear fast enough. The advice he gave me was to leave the engine like this and make the gearing longer. At the moment it's running 18/39 sprockets and 2.68 primaries. I do have a 19 tooth front sprocket but i'm wondering if it might be better to change the primary gear ratios. The down side to the gearing is I've got a primary gear ratio of 2,65 for the dry clutch assembly. Shame i didn't live close to Mutts as i would have pestered him every week until i was banned but i might have got a better insight into the gear ratios for big bore engines. I still don't think i'm in the boy racers club yet, i think i have gone from LC Caravan Club to LC Touring Club |

|

|

|

Post by donkeychomp on Jun 13, 2020 21:56:17 GMT 1

I think you're overbrenging it a bit...

Alex

|

|

|

|

Post by Tobyjugs on Jun 14, 2020 9:13:19 GMT 1

I think you're overbrenging it a bit... Alex That's very funny Alex |

|