|

|

Post by jon on Jan 25, 2015 22:05:46 GMT 1

Well, I finally started building rather than just collecting. Since I finished (it's never really finished) my LC hybrid, I've been collecting parts for my next build. I had so many parts left over (after changing my mind through the build) I thought I'd build another bike starting from the bits. Sounds logical, but I've done the same and changed my mind throughout collecting the bits. Here goes ...  This time I will be fitting an FZR600R front end, and an RGV swingarm with FZR or TZR wheels. Time to strengthen the frame. Cut out a scollup ...  and bend some tube ...   Welding next weekend.  Eat some cheese ! Can you guess why ? |

|

|

|

Post by dusty350 on Jan 26, 2015 20:45:10 GMT 1

Hi Looks good so far. Will you be able to access the tank mounting bolts ? Dusty  |

|

|

|

Post by jon on Jan 27, 2015 19:26:58 GMT 1

Dusty, there will be just enough gap between the tubes (8-10mm I expect) to get to the front tank mounting bolts.

I'll have to use a socket head and Allen key as there will not be enough room for a hex head and socket, but then I probably would have done anyway.

I'm more concerned about clearance of the new bars around the swingarm pivot with the engine. I will try it with the engine in situ before welding in the bars.

I don't really want to cut any off the flywheel side case, as it's a bit special being made from solid billet to standard shape.

Jon

|

|

|

|

Post by jaserdlc on Feb 2, 2015 20:47:29 GMT 1

Nice work

|

|

|

|

Post by jon on Feb 8, 2015 19:58:59 GMT 1

Been tidying my garages for a couple of weeks now. Finally got round to doing some more on the bike today. I knew I had to shorten the FZR yoke stem, but measured today that I need to remove 18mm. This is how it was...  Grind welds flat ... use HSS stepped cutter to remove metal ... turn down punch on lathe ... and punch it out ...  and its out ...  I will weld the bearing surface up to 30mm further up the stem, turn it back to 30mm, then shorten it, and finally weld it back in. |

|

|

|

Post by jon on Feb 23, 2015 22:53:40 GMT 1

Welded the stem, and turned it back. Must have got lucky the first time I did this, as I had to do this one twice. Clamped the yokes together with the forks to keep it all square ...  Welded it back together again  |

|

|

|

Post by Yogi on Feb 23, 2015 23:09:04 GMT 1

Nice welding,keep up the good work

|

|

|

|

Post by marsbar350 on Feb 23, 2015 23:32:41 GMT 1

yeah nice welding jon

must have big amperage weld that thick

|

|

|

|

Post by steve h on Feb 23, 2015 23:54:15 GMT 1

Neat bit of engineering  Not keen on the babybel though, I prefer a cheese with more errmm.... bollox, like stilton  you saving the wax? |

|

|

|

Post by jon on Mar 1, 2015 20:30:54 GMT 1

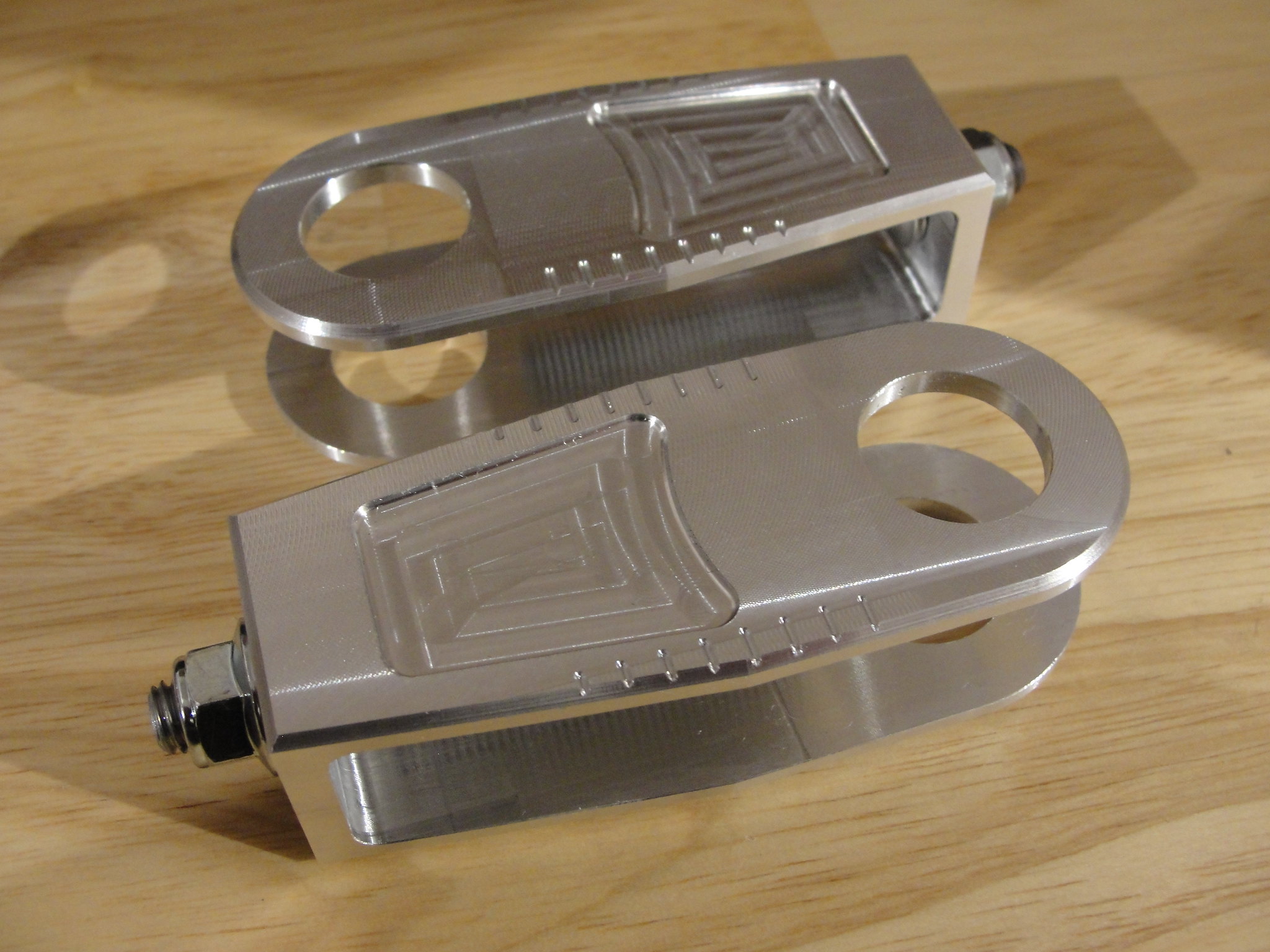

Marbar350, I'm getting used to my new welder. I welded the headstock on about 3/4 maximum (probably around 160 amps). Steve H, you are correct; I wanted the wax. Not only did have eat the s..t cheese, but the wax didn't work either! (I prefer a ripe camembert myself). I wanted to mould the taper on the FZR600R handlebar clamps to make some bars out of billet ally. Done it the old school method.  |

|

|

|

Post by jon on Mar 2, 2015 20:39:22 GMT 1

Headcoats, it might look easy once it's finished and photoed and on this forum. However you have not heard the swearing at times  I will anodize the bars before fitting to the clamps, but am not sure natural or black. Depends on final colour scheme. I'm very tempted with Yamaha USA colours, but who knows? |

|

|

|

Post by jon on Mar 23, 2015 20:46:38 GMT 1

Thought I'd get round to building a rolling chassis yesterday, but didn't get time. I had a half day today to finish it off, as the rest of the week looks like bad weather. Didn't finish till dark, but well pleased with progress. The trouble yesterday was the swingarm bushes I'd made to fit the RGV arm, with YPVS bearings. They were too tight really, and needed skimming today.  Put the bike together for the first time for a dry build ...   |

|

|

|

Post by copper99 on Mar 23, 2015 21:20:01 GMT 1

Quality work mate, keep the updates coming.

|

|

|

|

Post by 1966baz on Mar 23, 2015 21:24:32 GMT 1

A very good start Jon. Look forward to seeing the progress. Cheers.

|

|

|

|

Post by jon on Mar 29, 2015 20:28:54 GMT 1

I got to machine some swingarm bobbins this weekend. The centres are steel which I will get zinc plated.  I then had to make some paddock stand hooks because I will be getting a front wheel chock.  I also received a set of chain pulls from NK on Friday, they are a new design with R6 adjusters.  |

|

|

|

Post by jon on Apr 8, 2015 19:56:02 GMT 1

Picked up a spare tank from reggieperrin (nice to meet you Alan). I have got 2 sets of bodywork for this bike, because I really cant decide between a fairing or not. I really like the idea of building a Kenny Roberts style bike with a fairing for 1up only, but then I quite like the idea of swapping over various things in a day to create a different bike for 2up and probably a different paint scheme. Anyway meet the twins ...  I asked my local plater today about removing any rust internally, and he said he'd put it in his chemicals overnight, but it might not remove 100% of the paint externally, so I stripped them with some industrial strength stripper (not like the Nitromores boll..ks they sell these days in case a child should drink it). |

|

|

|

Post by mercwagonman on May 17, 2015 20:58:10 GMT 1

I like the idea of swapping the panels over to make a different bike, doing the same myself...nice build  |

|

|

|

Post by jon on Sept 20, 2015 20:00:57 GMT 1

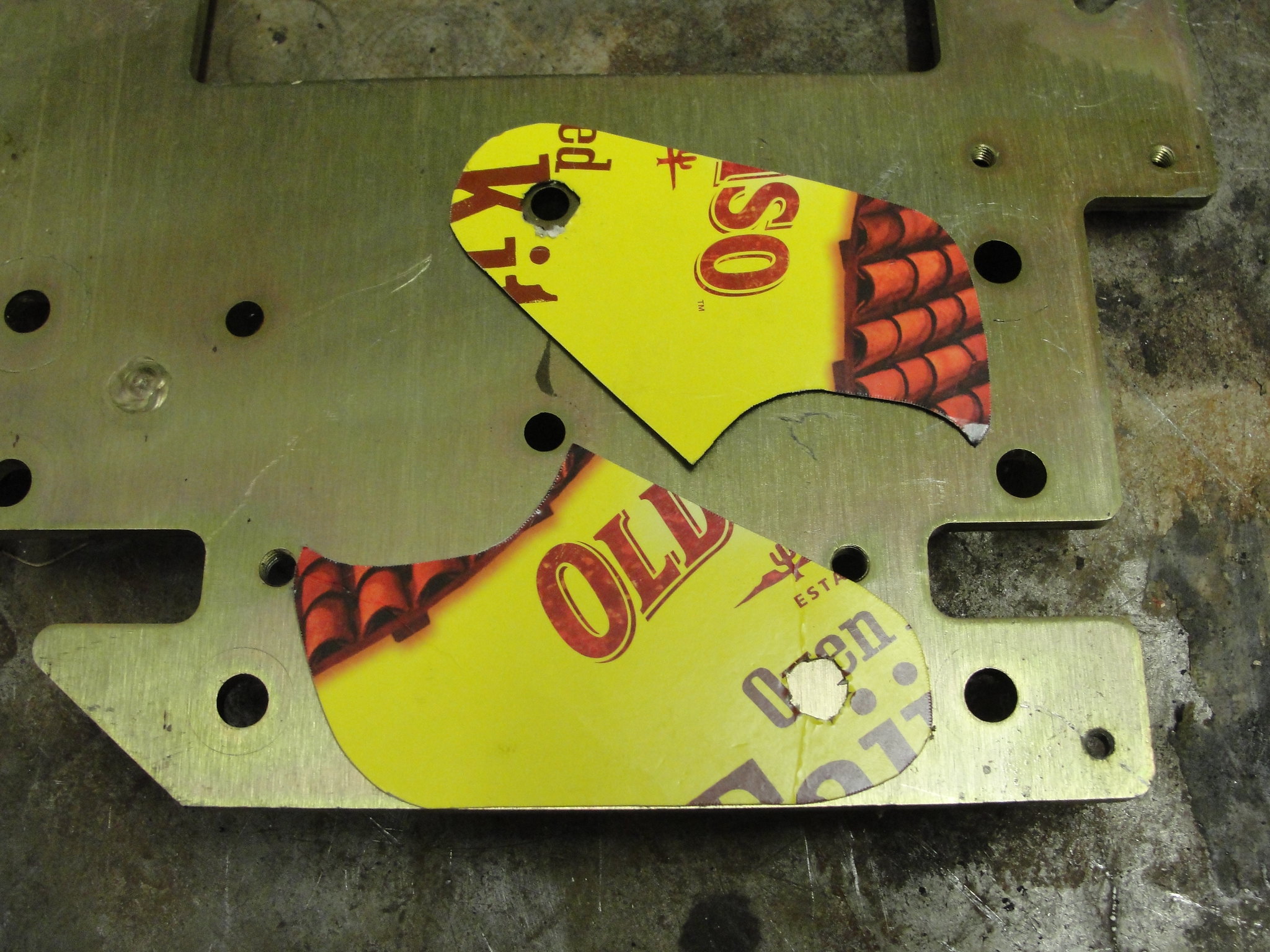

I cannot believe its been months since I last posted. I've had several distractions, including a new YPVS which I will probably do a build thread on also! I've been collecting parts for this build, but have not really made any advances until today. Next month (I've been waiting 3!) Gibsons is going to make some bespoke pipes. That has prompted me to do all the mods on the frame which might affect the exhausts. I'd bought an NK kit to fit my RGV P model arm into a YPVS. Trouble is you loose the centre stand which I really like on a bike. After fitting the kit I could not help thinking it was from original measurements of a bike when it was first done. Now there are tolerances on all production lines, but I couldn't help thinking my bike was actually central on the existing bracket, so the kit made it offset by a small amount! I decided to measure my bike for the centre line. First I bolted in a square bar from the top shock mount, and measured it against new spacers I'd made to keep the plates central.  Once I new it was central, I made a jig off the top shock mount, swingarm mounts and the new centralised plates.  Then I made some new plates that didn't need bolting through the centre stand mounts courtesy of 'old elpaso' and the metal from a old 'stannah' stair lift.  Then after turning a spindle to mount the middle, I welded it all up.  |

|

|

|

Post by unrealedd on Sept 20, 2015 20:18:29 GMT 1

Some nice work going on there and your welding is far better than mine. looking forward to seeing this unfold.

|

|

|

|

Post by LC_BOTT on Sept 20, 2015 20:58:59 GMT 1

With your skills, I did wonder why you bought the NK kit, obviously well within your scope, (are you selling it now?) There's several 'specials' being done on the forum lately and this is another to raise the bar  |

|

|

|

Post by JonW on Sept 21, 2015 0:41:58 GMT 1

What a great thread! Loving the engineering on this, and the first pic is wat i would term 'the perfect start', its how I start most of my builds. Once you have a frame you can do anything, why start with a whole bike  If you dont need the NK kit now, and want to sell it I know someone who wants one in Aus for his build, drop me a PM and i'll hook you up. |

|

|

|

Post by reggieperrin on Sept 21, 2015 11:12:23 GMT 1

Looking good so far Jon..

|

|

quans1000rr

L plate rider.

here for a good time not a long time

here for a good time not a long time

Posts: 11

|

Post by quans1000rr on Sept 21, 2015 14:32:07 GMT 1

Top keep pics coming !!

|

|

gsexr

Thrash Merchant

Posts: 352

|

Post by gsexr on Sept 23, 2015 21:46:13 GMT 1

Great thread

Keep it coming, luv to see the engineering

|

|

|

|

Post by jon on Sept 27, 2015 20:10:45 GMT 1

Sorry LC-BOTT, I didn't see your request for the NK bracket till late last week. I phoned NK on Friday to ask him if the brackets were the same for a banana arm, and he confirmed they are. Just need a set of dog-bones @ £40. This weekend has been very slow getting stuff done. I did manage to make my centre stand fit as I wanted it though. The holes were ever so slightly elongated, so I decided to bush the stand. As standard they are quite a bit narrower than the mount so I decided to make a bush as wide as possible to fit the bracket to spread the load. I also turned up some lovely stand bolts out of 303 stainless as I didn't have any.  |

|

|

|

Post by jon on Oct 29, 2015 20:58:22 GMT 1

I've been waiting 4 months since I asked Tony to book me in at Gibson's for some pipes to be made. They are for low to mid range, and the same design as a set made for someone in YPM. They are slightly bigger bore than Gibson's Allspeed copies which I have on my LC with TZ style cans. Today he phoned me to tell me they were done. Needless to say I couldn't resist picking them up asap. Took a couple of snaps up there. Well pleased with the look of them. They tuck in nice and tight as they were made on the bike. Stainless brushed, and the heat marks left on. I think I'm even going to leave the numbers marked on each cone in ink.   Got them home and they were thoroughly QC inspected (not by me though).  |

|

matt7

Thrash Merchant

Smell of the 2 stroke & the roar of the crowd

Smell of the 2 stroke & the roar of the crowd

Posts: 445

|

Post by matt7 on Oct 29, 2015 21:04:17 GMT 1

The pipes look great, as does the bike they're going on !

Pretty pussy too lol

Cheers

Matt

|

|

|

|

Post by jon on Nov 8, 2015 21:01:45 GMT 1

|

|

|

|

Post by unrealedd on Nov 8, 2015 21:10:43 GMT 1

Bloody loverly work there and coming along nicely.

|

|

|

|

Post by wroughtironron on Nov 8, 2015 21:37:18 GMT 1

Fabulous pics and skills - well done sir !

|

|